Watches, primarily made of metal, are products of industrial manufacturing, and nowadays, computers are mainly used in their design process. As a result, many designs tend to become inorganic. In this model, by incorporating curves and rounded edges into details such as the indexes, side surfaces of the case, bezel and case back edges, and the crown, a balance is achieved by adding organic elements to what could otherwise be an inorganic watch design. By adopting details that could even be described as biological in a sense, the shape is made moderately flexible, allowing it to be worn comfortably without psychological resistance or a sense of harshness for the wearer.

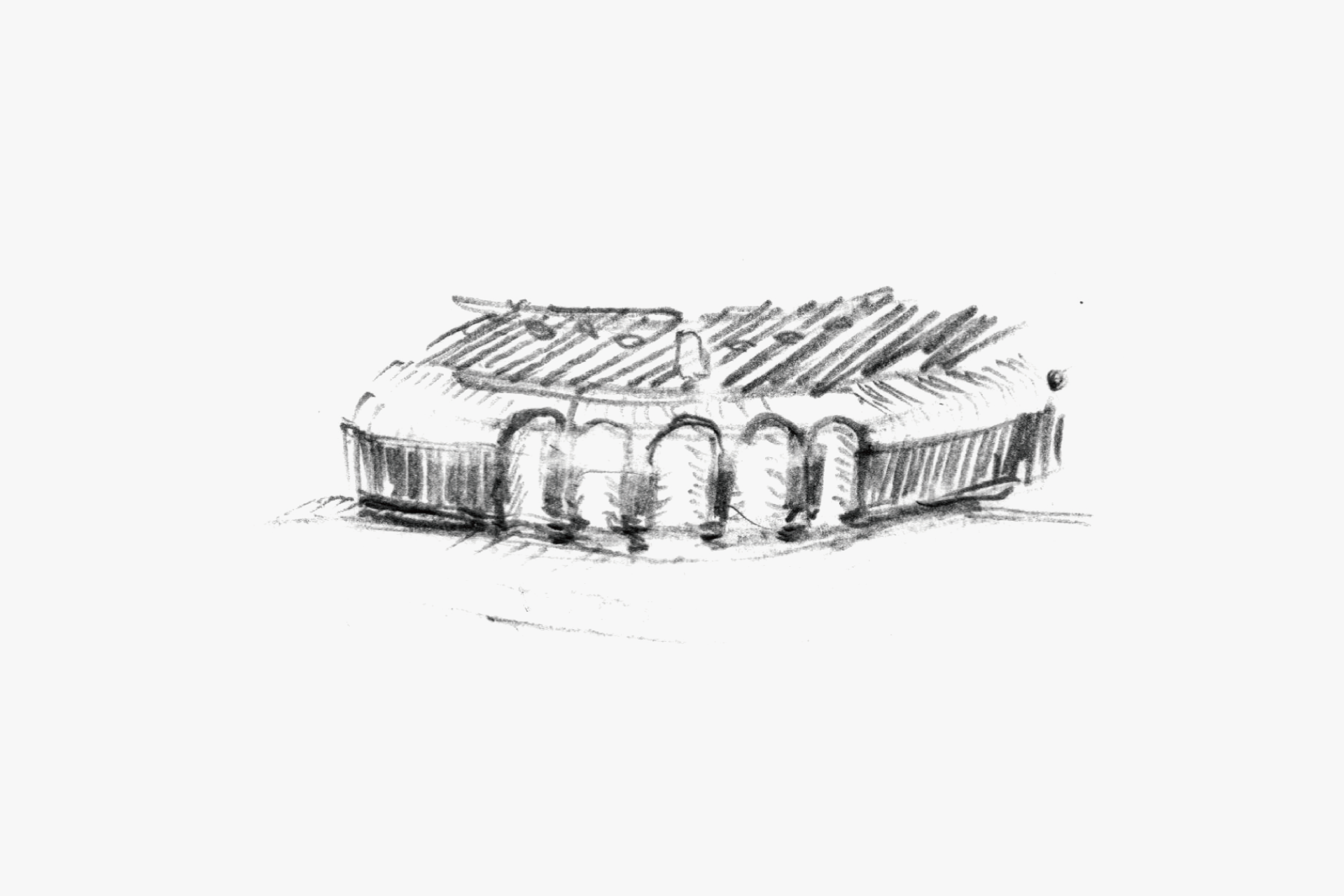

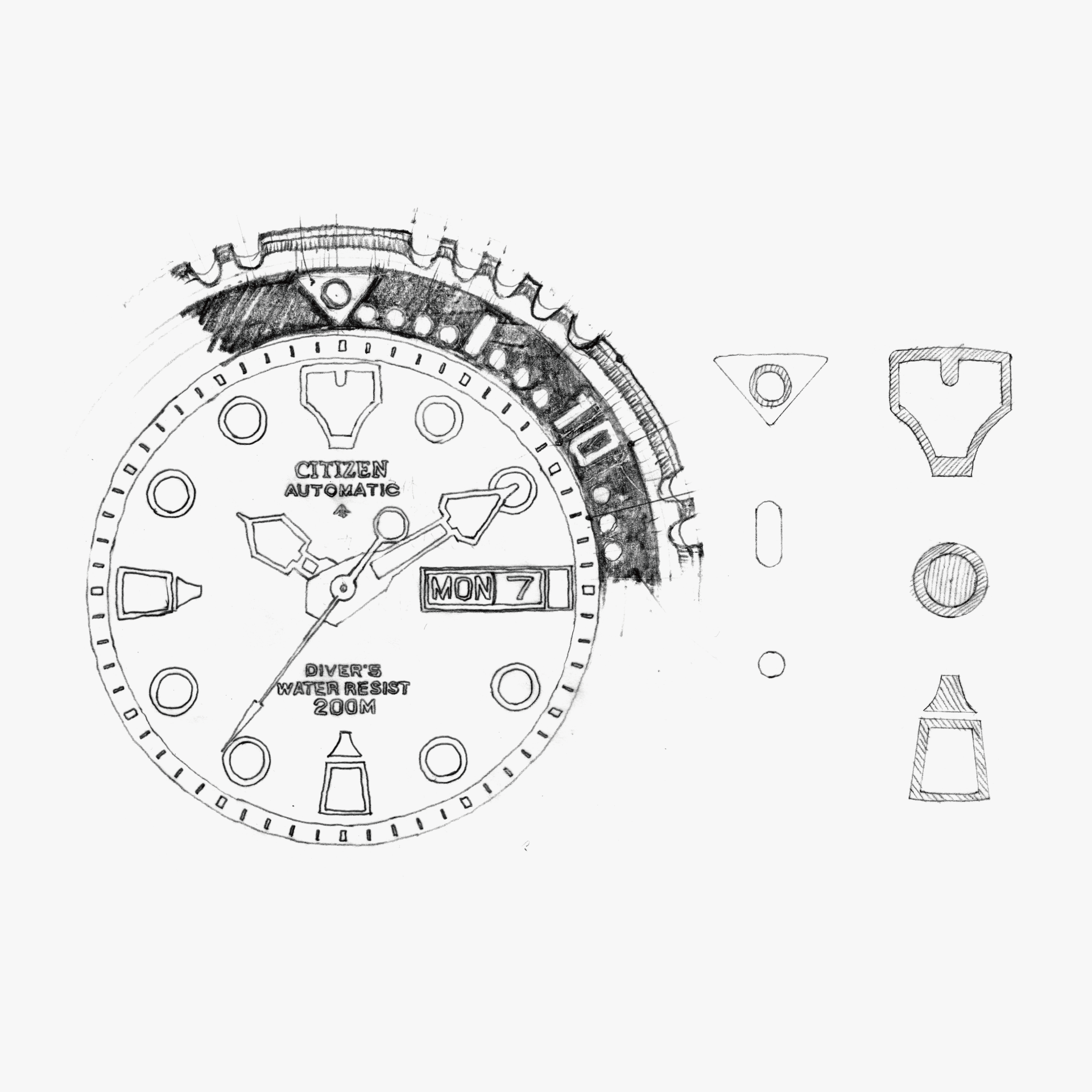

A model that stays true to the basics of a diver's watch. Its individuality is expressed through attention to details such as the indexes.

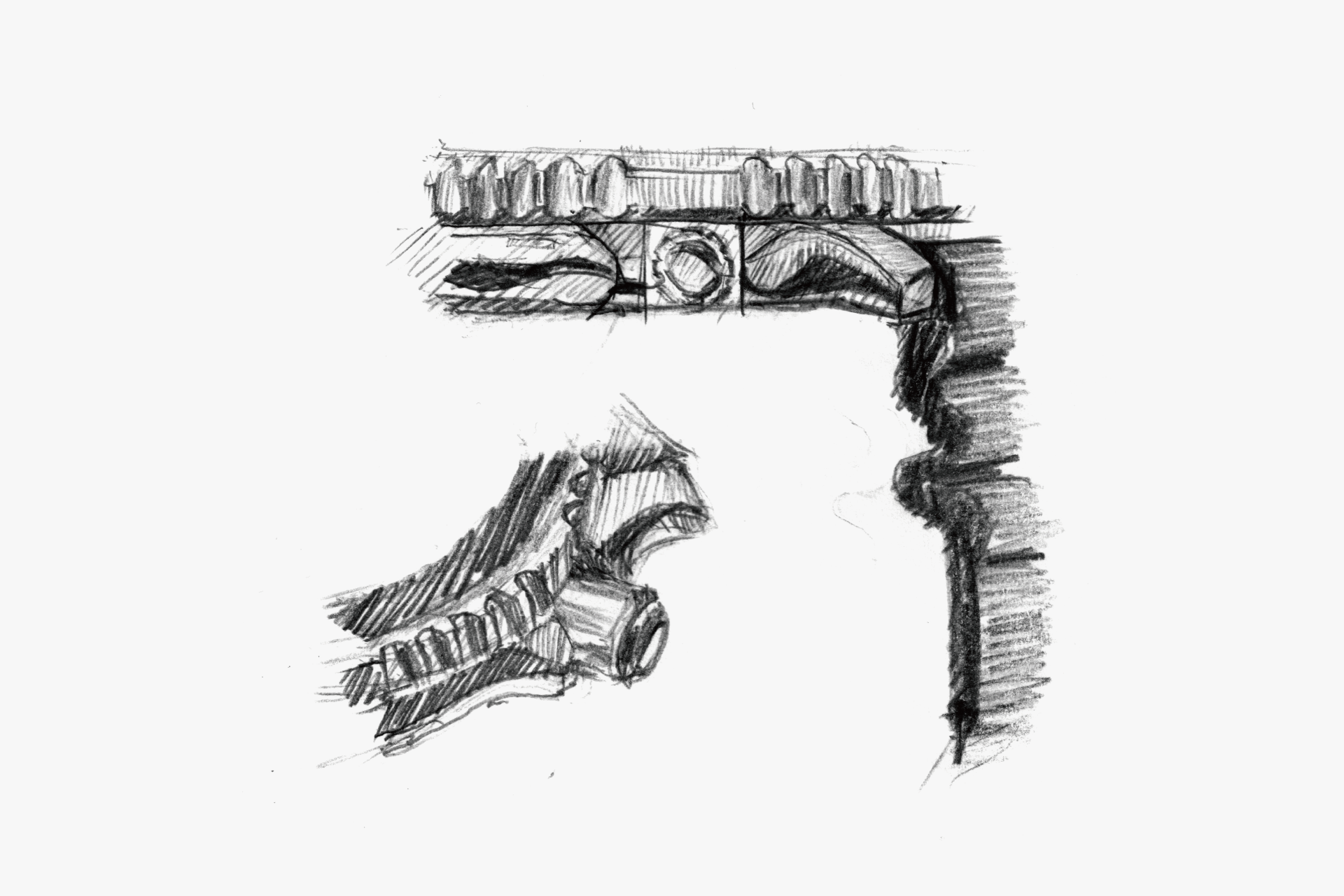

The corners of the bezel feature large rounded curves, making the shape comfortable to the touch and to the eye. The five notched sections improve operability and also add to the unique character of the design.

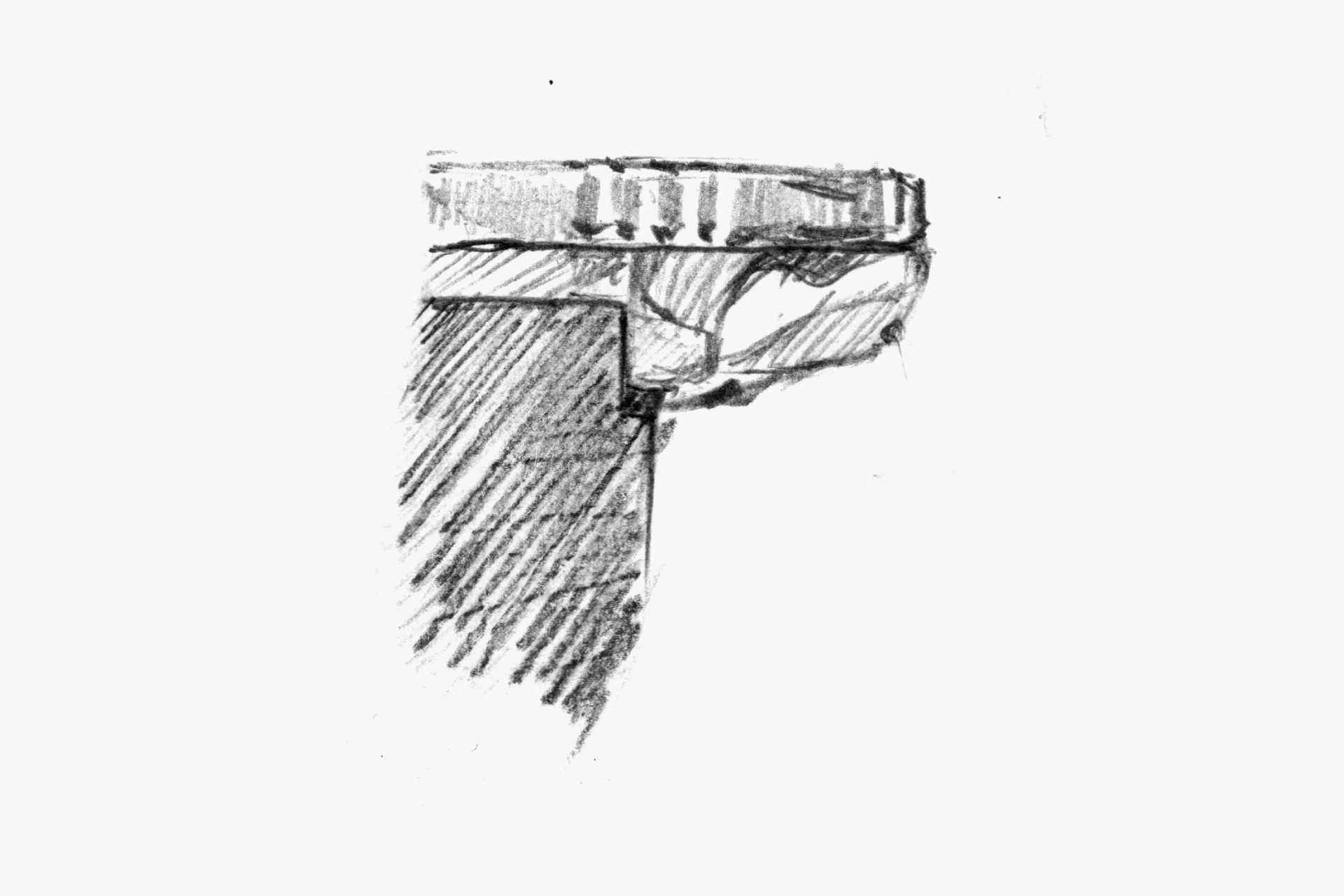

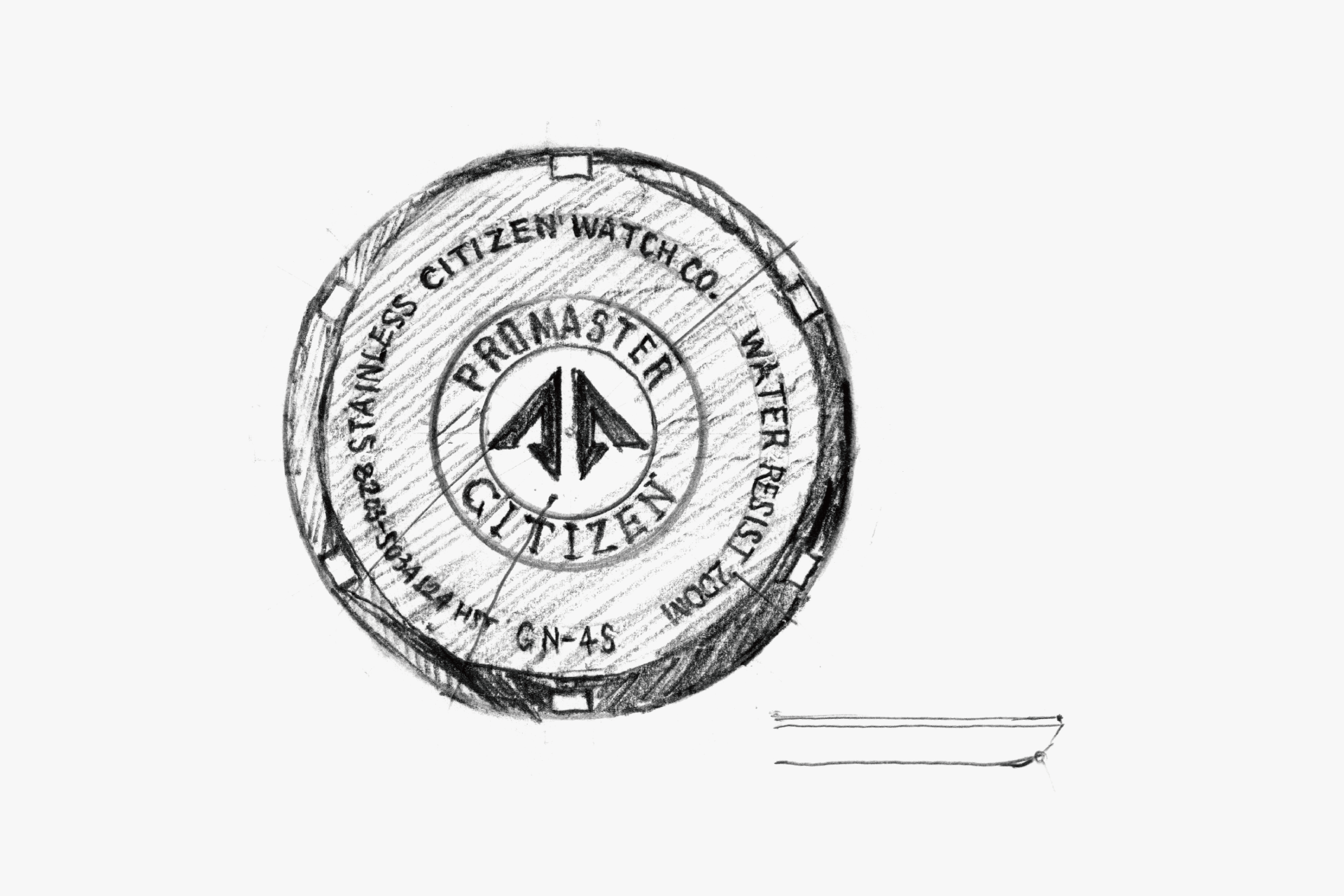

The side surface of the case is a smooth curve. Combined with the polished finish, it gives a lustrous impression.

The transition from the side surface of the case to the crown guard is smoothly connected from curve to curve.

The top surface of the crown is indented like a crater, giving it an organic impression that adds to its friendliness.

Many circles and curves are incorporated throughout the elements of the dial. This creates a gentle impression and a shape that feels welcoming and easy to accept.

A case back with no edges. The parts that touch the hand have no corners, giving a comfortable and familiar impression.

ENGINEER'S EYE

Immortal Movement

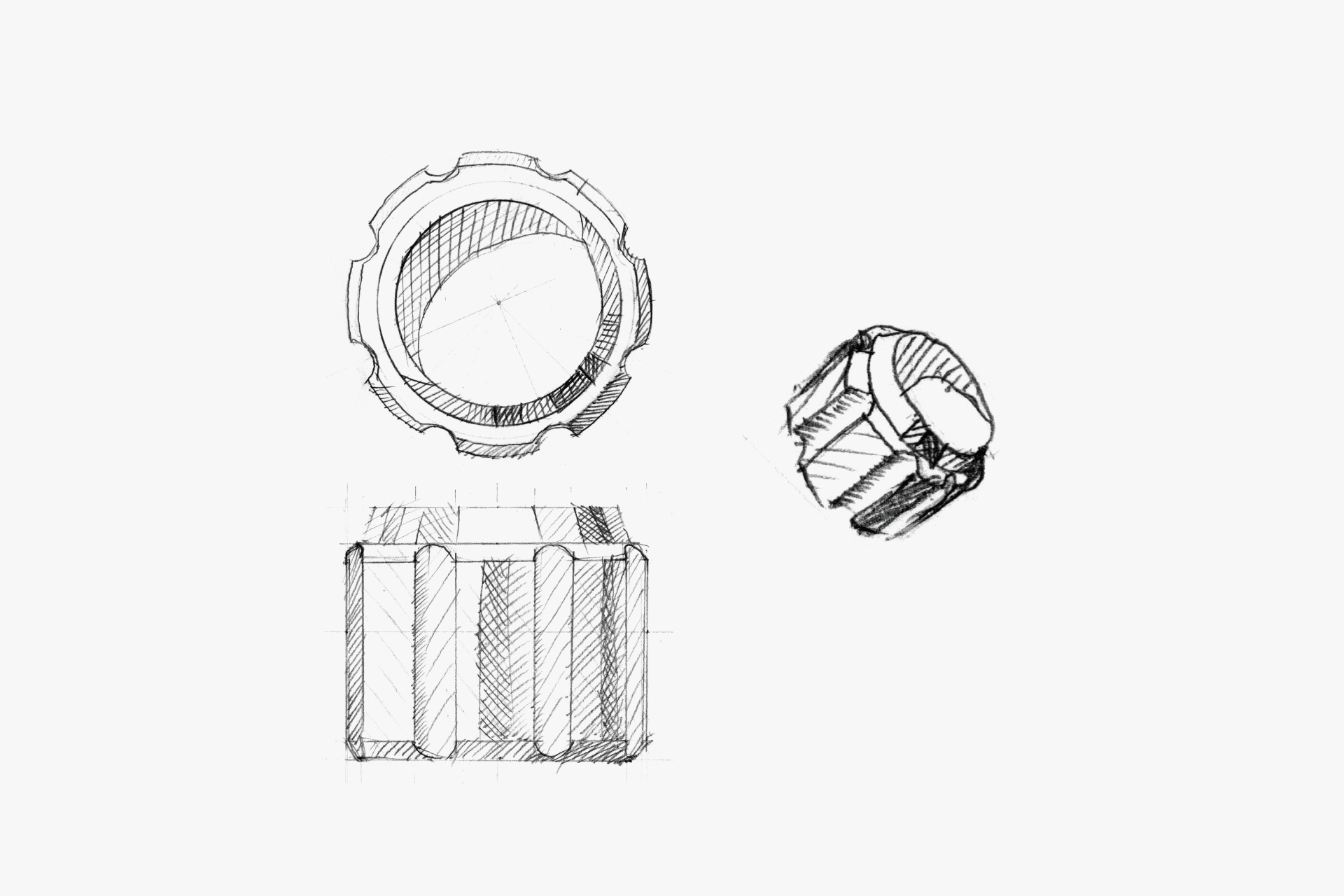

In a sense, the Cal. 82-series automatic movement is an “imperishable” movement. Since its release in March 1976, it has continued to be produced to this day. Even in the 1980s—when watches were going electronic and many thought mechanicals had become a thing of the past—it was steadfastly kept in production.

Its hallmarks are robust core performance and high manufacturability. In the early stages of development, before it was assigned the caliber number 82, it was referred to by the code name “ST-1,” with ST standing for “standard.” It offered a highly versatile size (φ25.6 mm × t5.67 mm) with date and day, and what’s more, both indications could be corrected by rotating the crown pulled out to the first click. By today’s standards that may seem obvious, but at the time many watches did not offer this.

In terms of performance-related features, it follows the fundamentals of mechanical watch design. For example, for the hairspring stud, a “triangular stud” was adopted so that even after disassembly and reassembly during overhauls, the factory-adjusted center of the hairspring is less likely to shift. The regulator is a capped type to prevent the hairspring from slipping out due to shock, thereby improving reliability.