This watch has two key features. One is that it uses titanium as its material. The other is that, although the dial is made of metal, it generates power and operates using light.

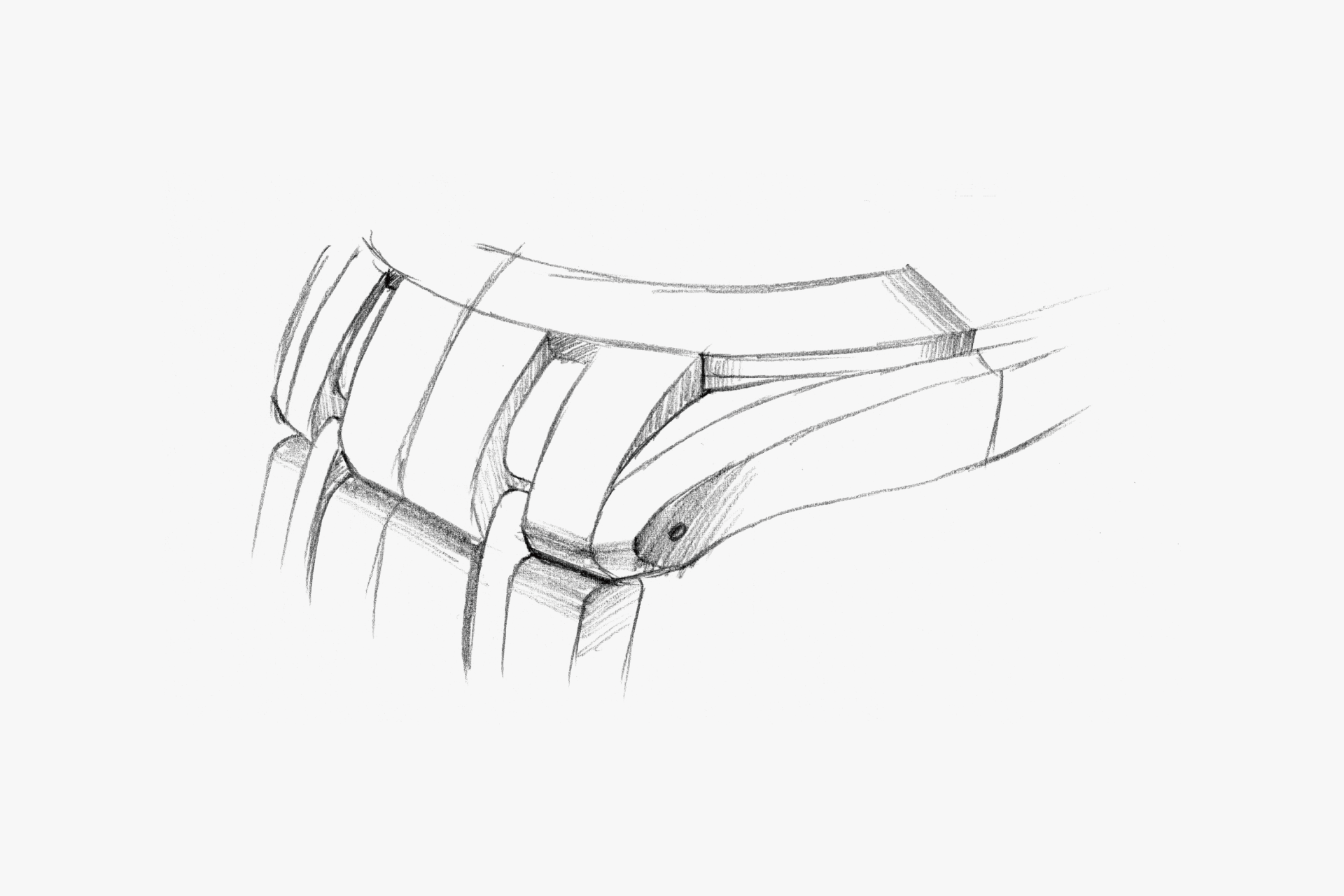

With titanium, it is more difficult to create sharp edges compared to stainless steel, which often reduces its appeal. However, this challenge is overcome through organic shapes and a bold polished finish.

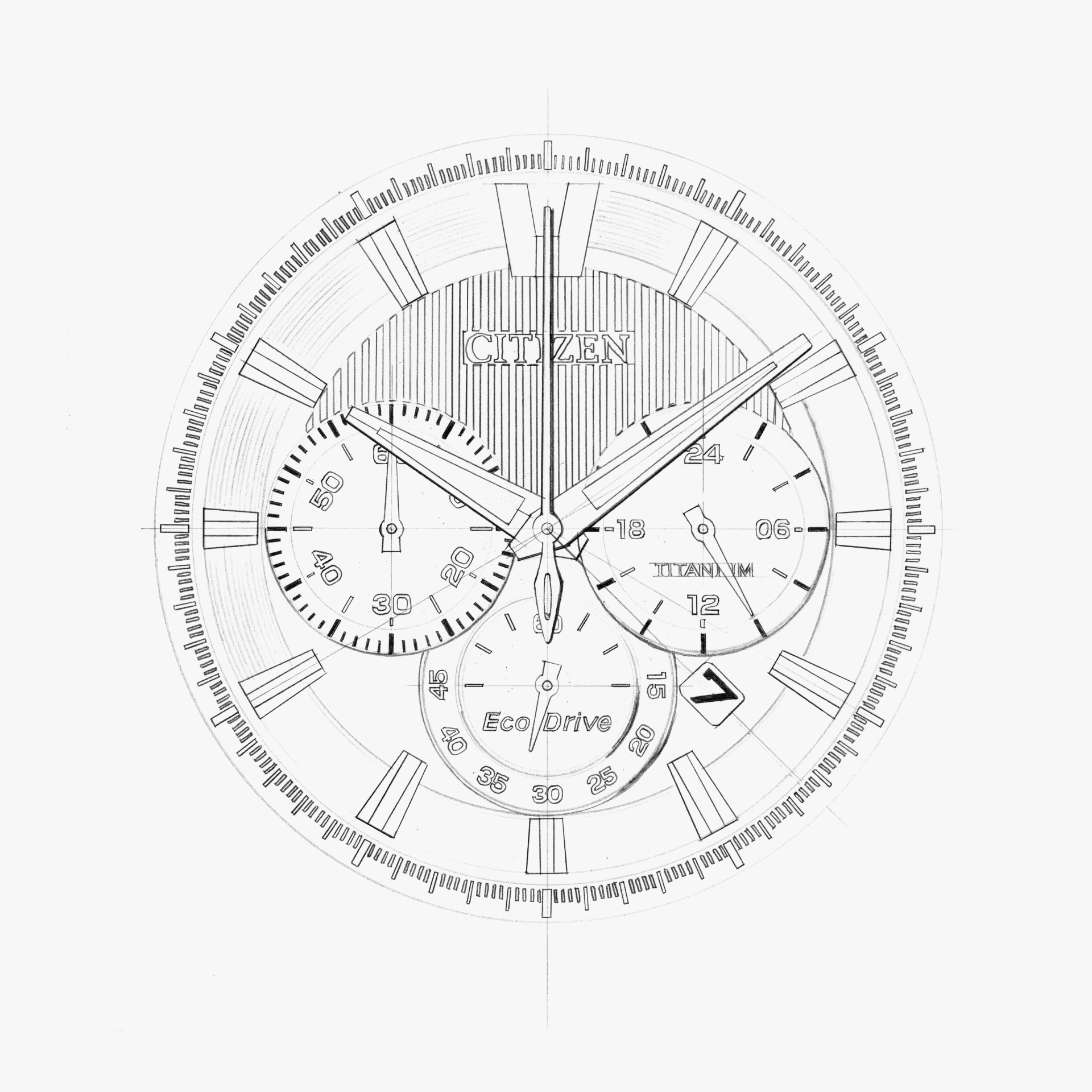

The dial generates power by receiving light only through the three sub dials, allowing the rest of the dial to be made of metal. Unique processing further enhances the appeal of the metal dial.

By combining the bold polished finish of titanium with the distinctive allure of the metal dial, the overall design is well-balanced and crafted to easily catch the consumer's eye.

It is a product that immediately attracts attention and clearly conveys its appeal to consumers.

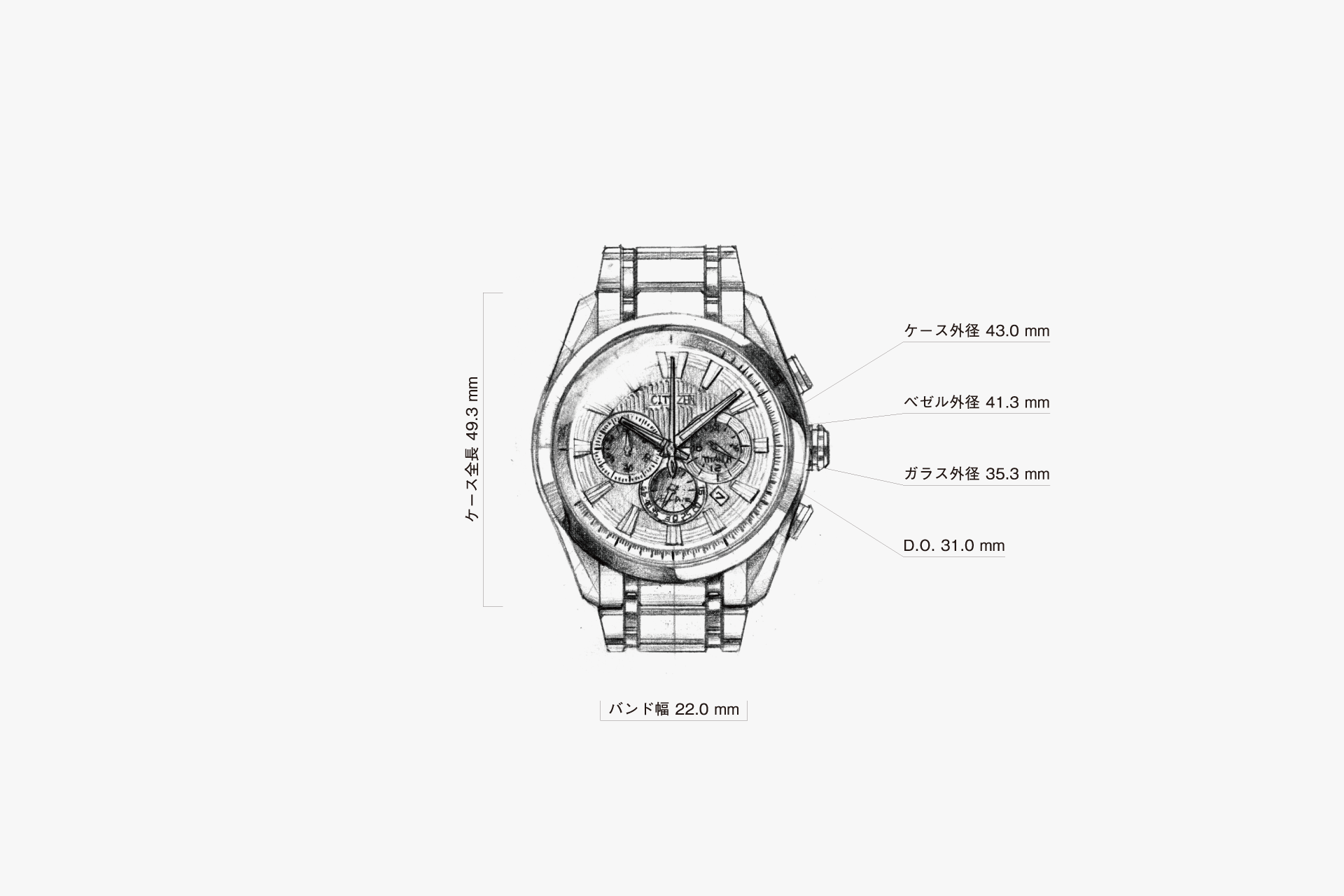

The balance of the finish is designed so that the polished surface looks beautiful.

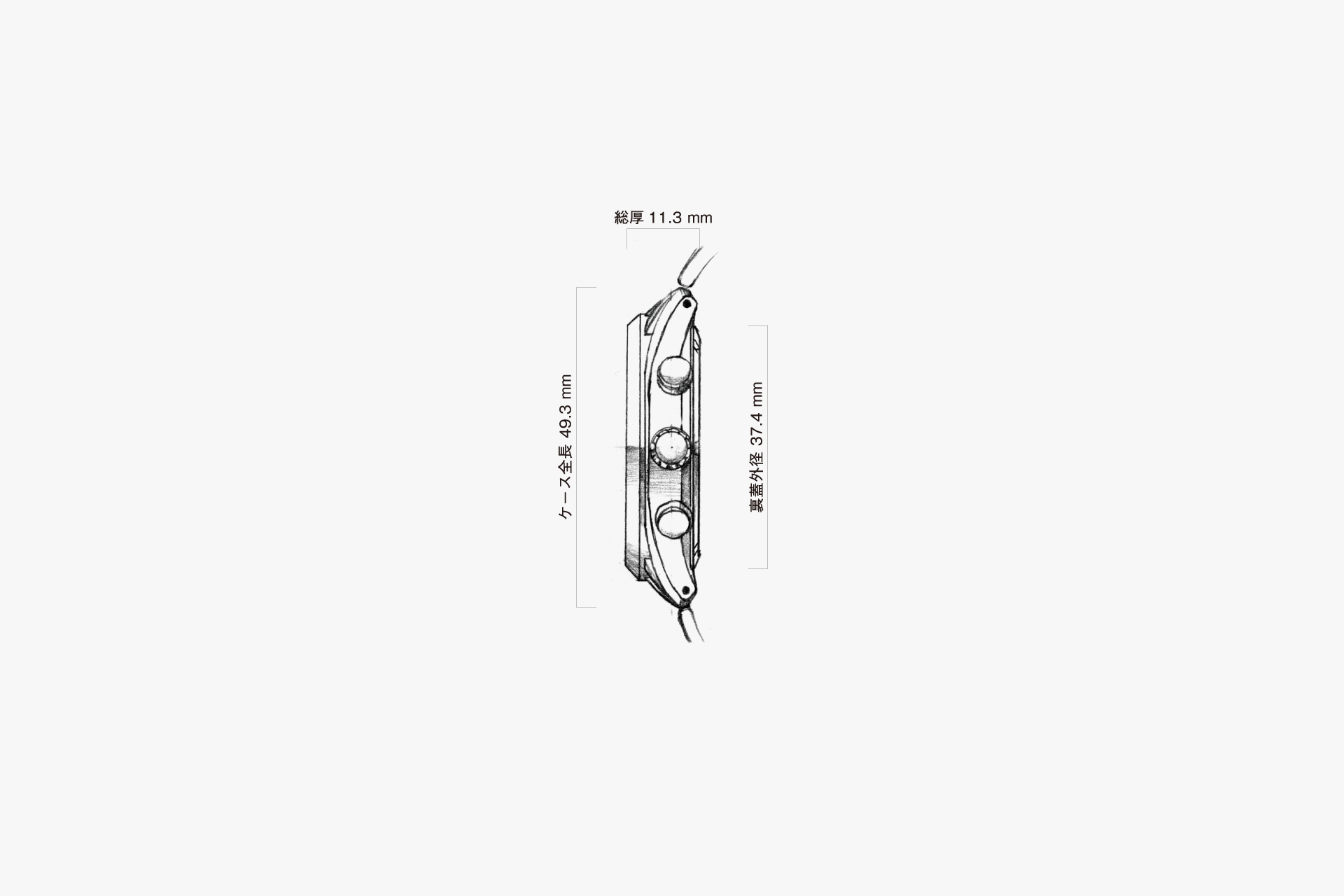

On the side surface, the balance between polished and matte finishes is almost 1:1.

By skillfully alternating polished and matte finishes, the surfaces are given clear definition.

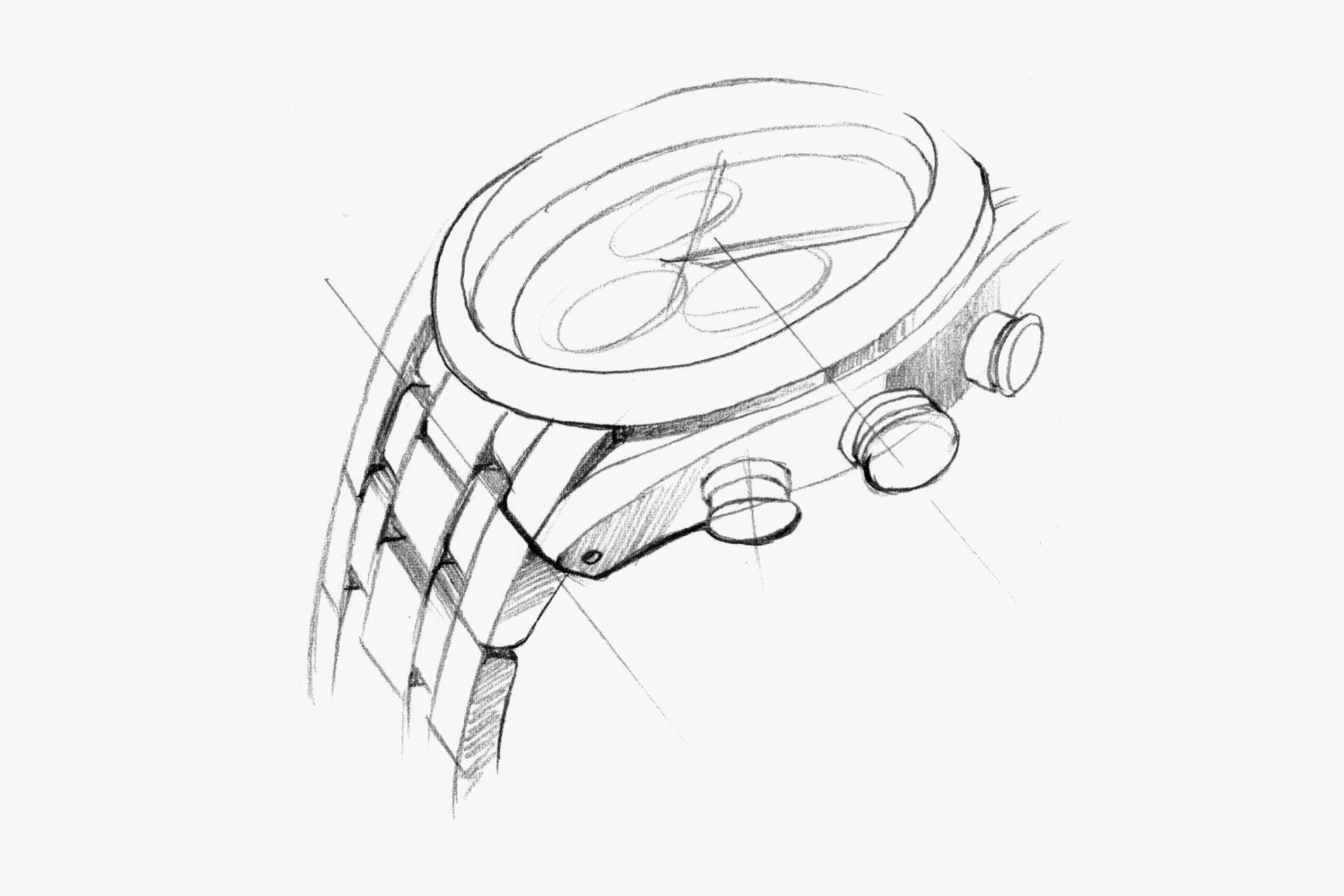

By organically blending the surfaces of the case and the band, a supple form is created.

To clearly distinguish between polished and matte areas, the design incorporates pronounced steps, with the finishing process in mind.

By using metal for the dial, color reproduction is enhanced and the finish appears even more beautiful. The distinctive 12 o'clock index improves legibility. The striped recesses and protrusions around the CITIZEN logo give a sporty yet dressy impression, making it suitable for everyday use.

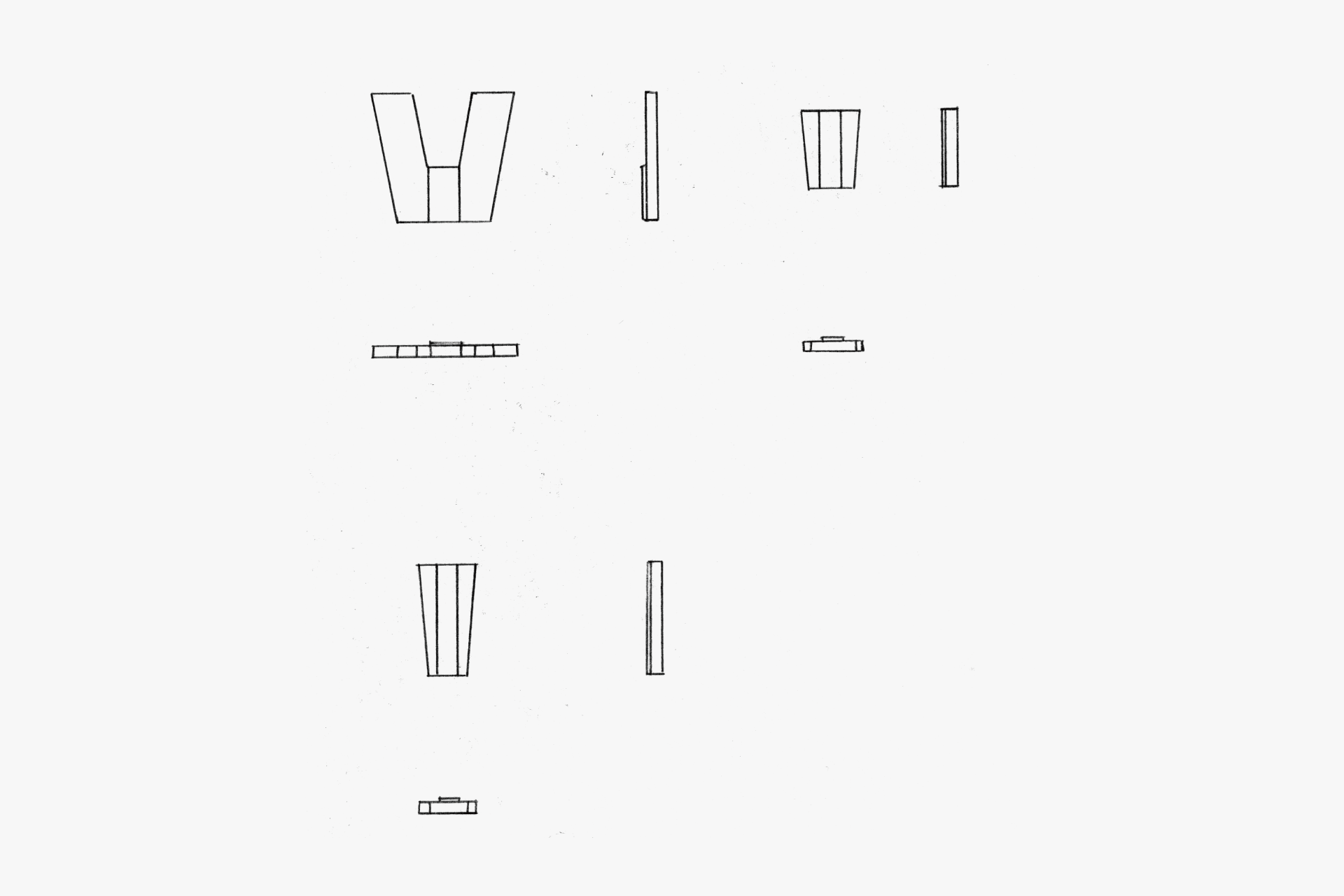

By designing the indexes to be simple and symbolic rather than complex, the watch gives an impression that is widely accepted.

Light is received and power is generated through the sub dials at 12, 6, and 9 o'clock. While the solar cells can be faintly seen upon close inspection, their presence is minimized by the use of numerals and markers.

ENGINEER'S EYE

Accumulation of Improvements

“Ti+IP” = the second installment in the titanium + ion plating series. Following the success of the first model, development began as a global model.

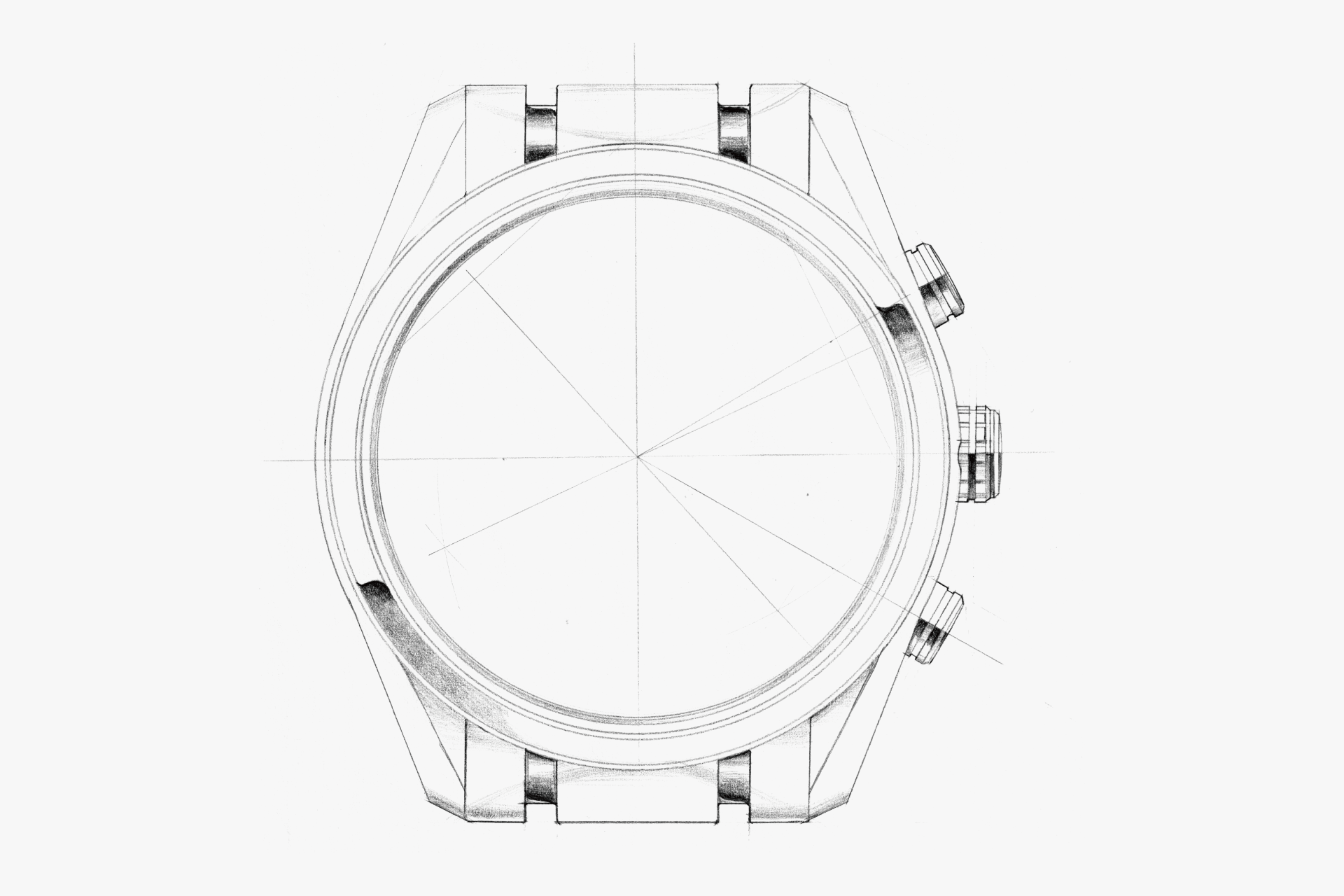

As a new design direction, a proposal was devised to eliminate the end piece and make it part of the case. To verify whether a new structure could be realized without compromising the design, we created multiple types of samples and repeatedly discussed them with planners and designers. In particular, we cooperated with the factory on meticulous refinements, such as changing the ridge around the lugs to a shape that makes machining precision easier to achieve, resulting in a sharp, compelling form.

It remains a long-selling product that continues to be offered even today.