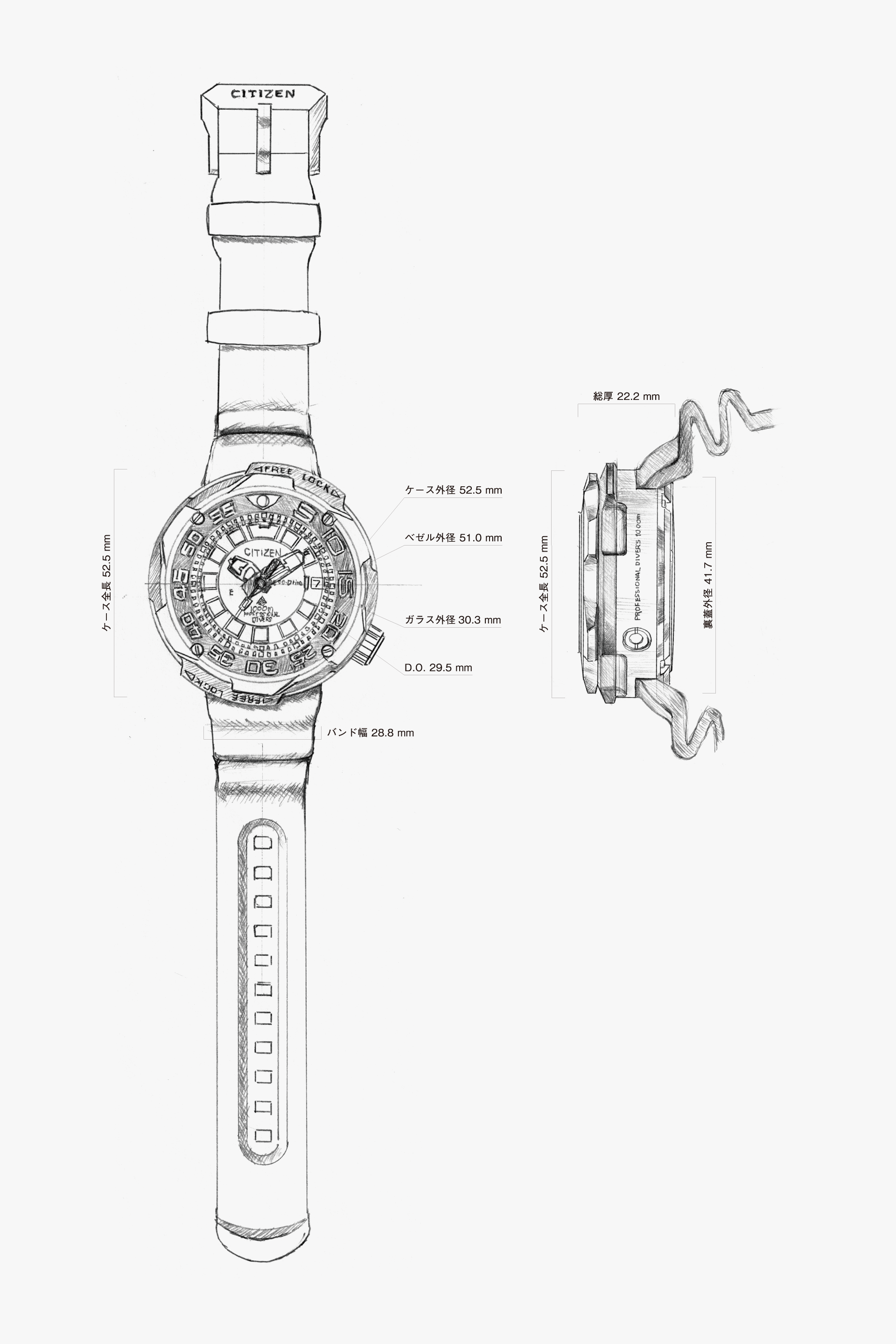

This diver's watch is a model that took on the challenge of how to give an attractive design to a core that is engineered to withstand depths of 1,000 meters and reliably function in such harsh environments. In other words, the major challenge was how to use design to bring together the 'stacked box structure and form'—resulting from the addition of a bezel misoperation prevention mechanism to a case that must already be thick to withstand high depths.

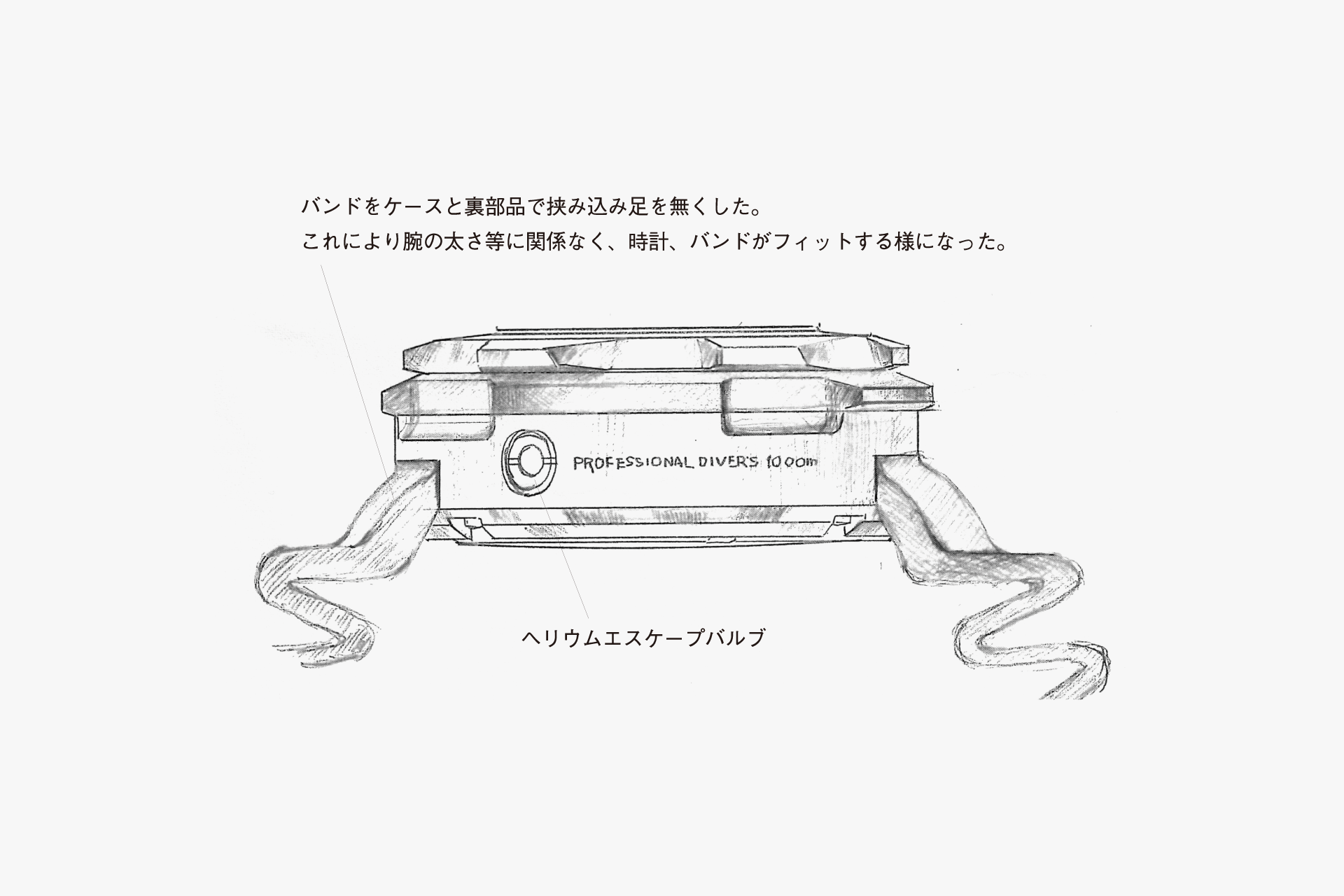

When viewed from the side, the use of polished and matte finishes ensures that the eye does not focus on any one area, and the insertion of black components prevents the watch from appearing as a thick mass. Additionally, by making the outer circumference of the bezel a slope that spreads downward and the underside a reverse slope, the watch avoids looking like a rugged metal block and instead gives an organic, almost sea creature-like impression, reminiscent of a turban shell or sea anemone. This is a good example of design and function fusing together, giving a diver's watch a marine organism-inspired appearance.

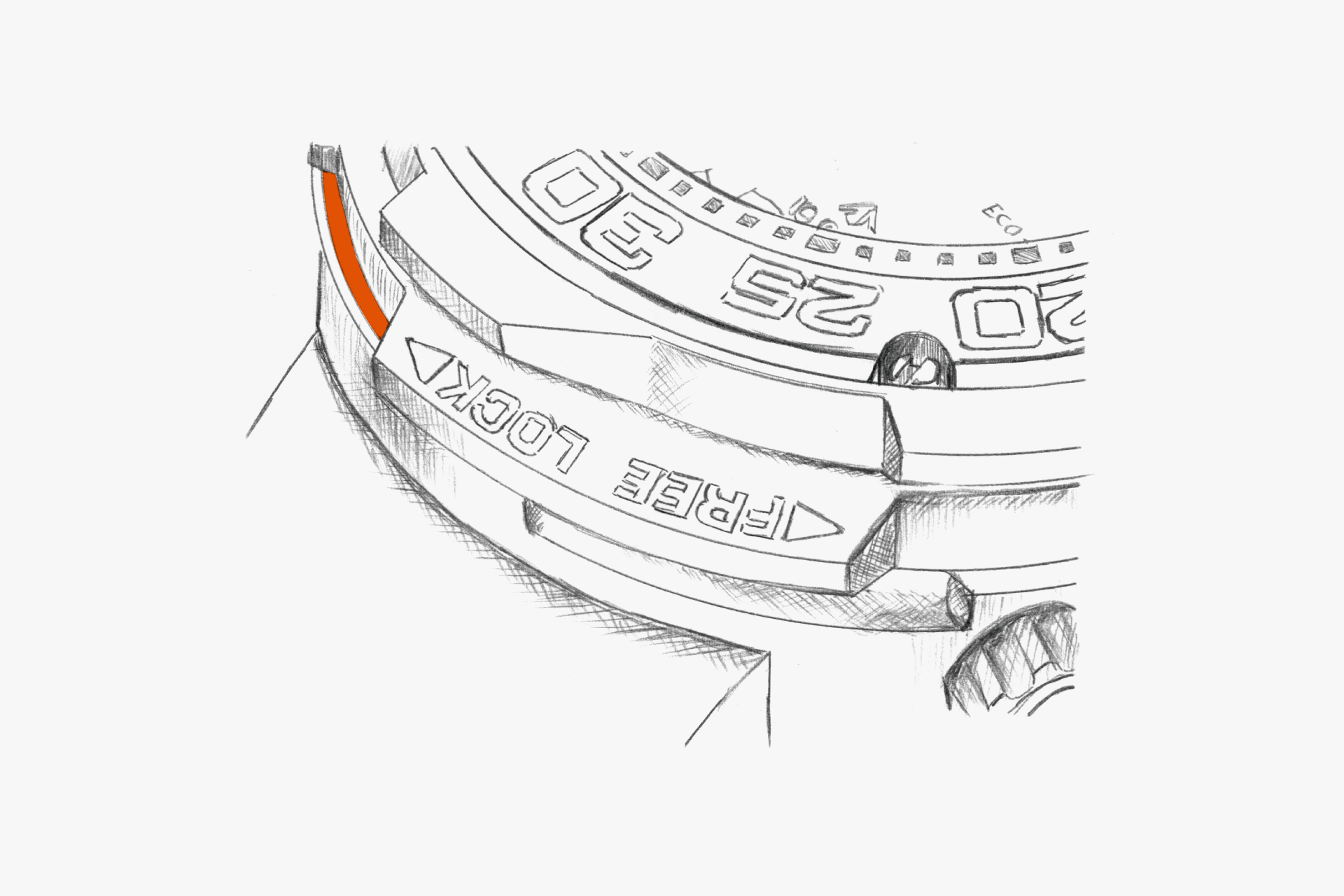

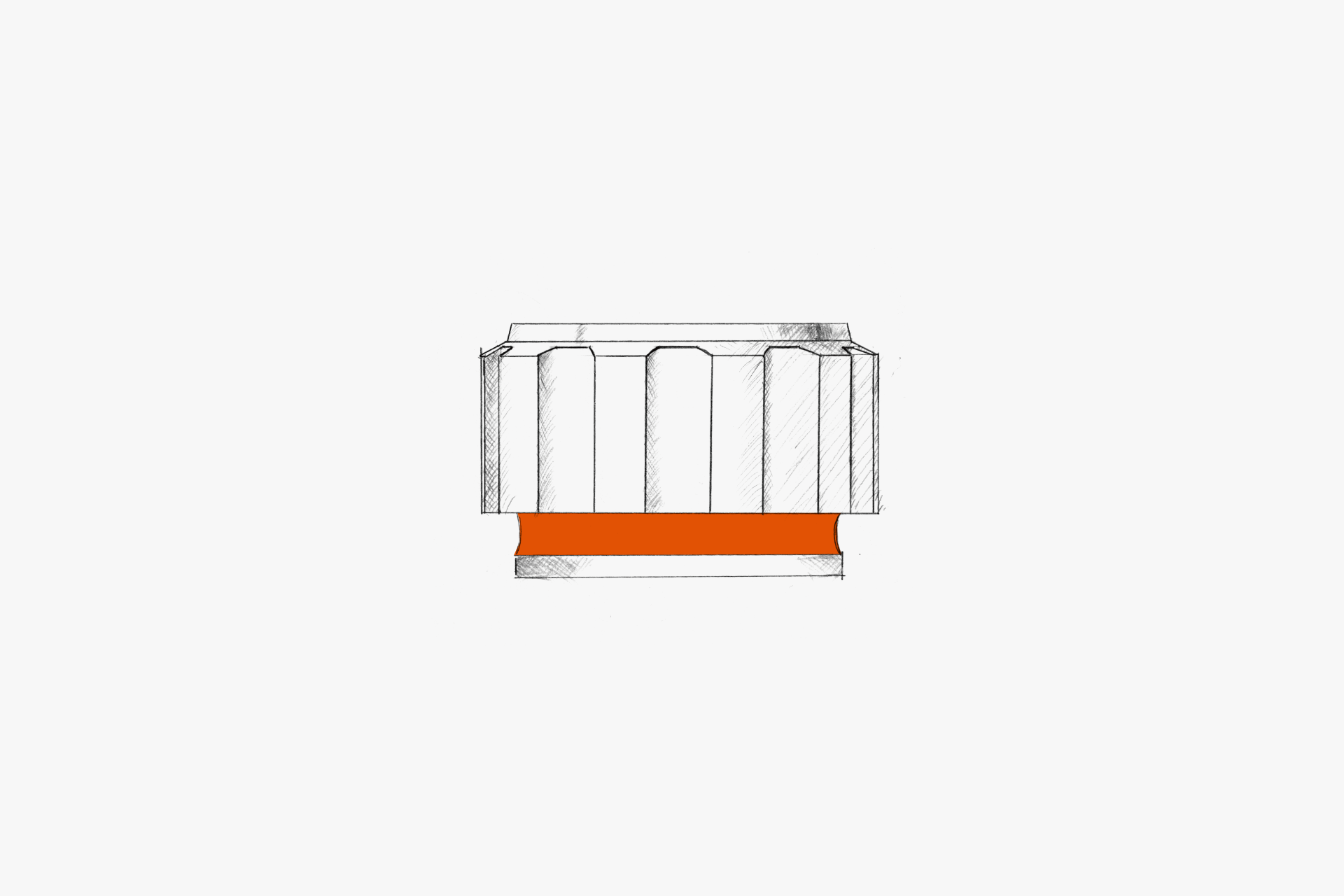

By rotating the ring outside the bezel, the locking mechanism is engaged to prevent accidental rotation of the bezel. When the lock is released, orange can be seen from beneath the component, allowing users to visually confirm whether the mechanism is engaged.

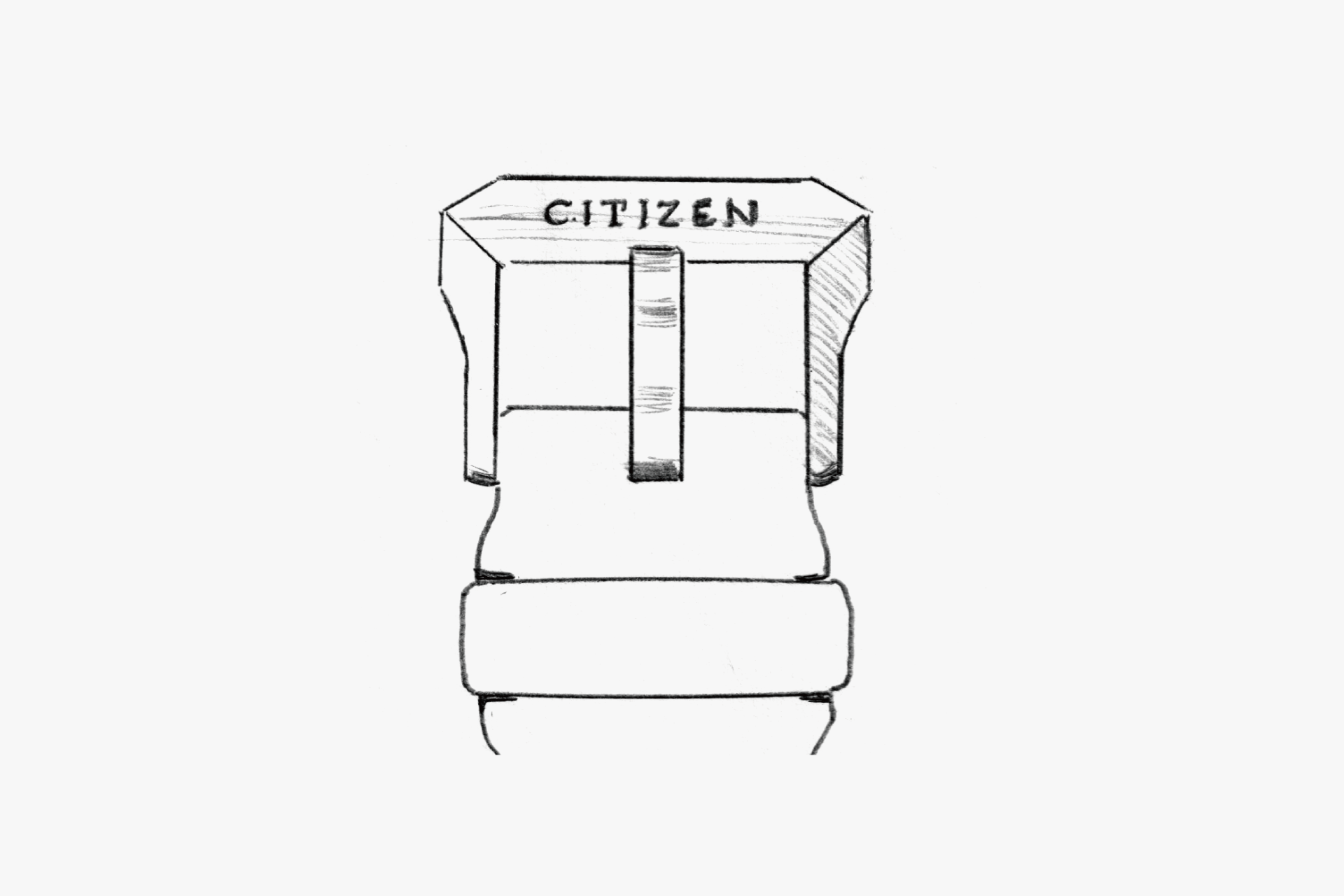

Each component is layered according to its function, resulting in a shape and structure that is easy to handle even when wearing gloves.

Although the overlapping components make the watch thick, each part is given a slope to prevent unnecessary snagging or damage. The hard shapes are complemented by slopes and curved surfaces, giving it a marine organism-like feel.

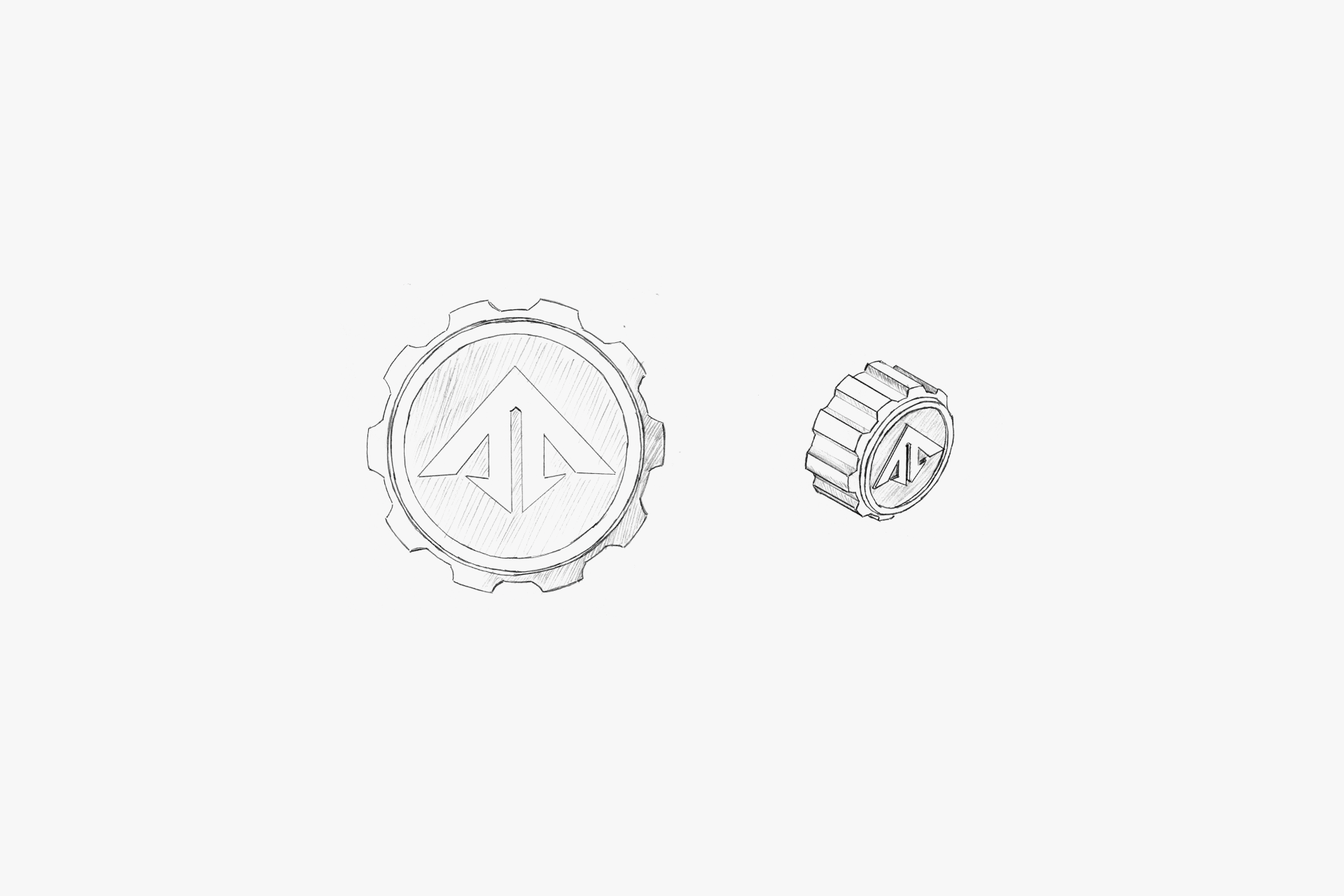

A subtle, large curve is applied to the entire surface, and a mark created by coining is placed at the center of the luxurious case back, giving it a professional-use feel.

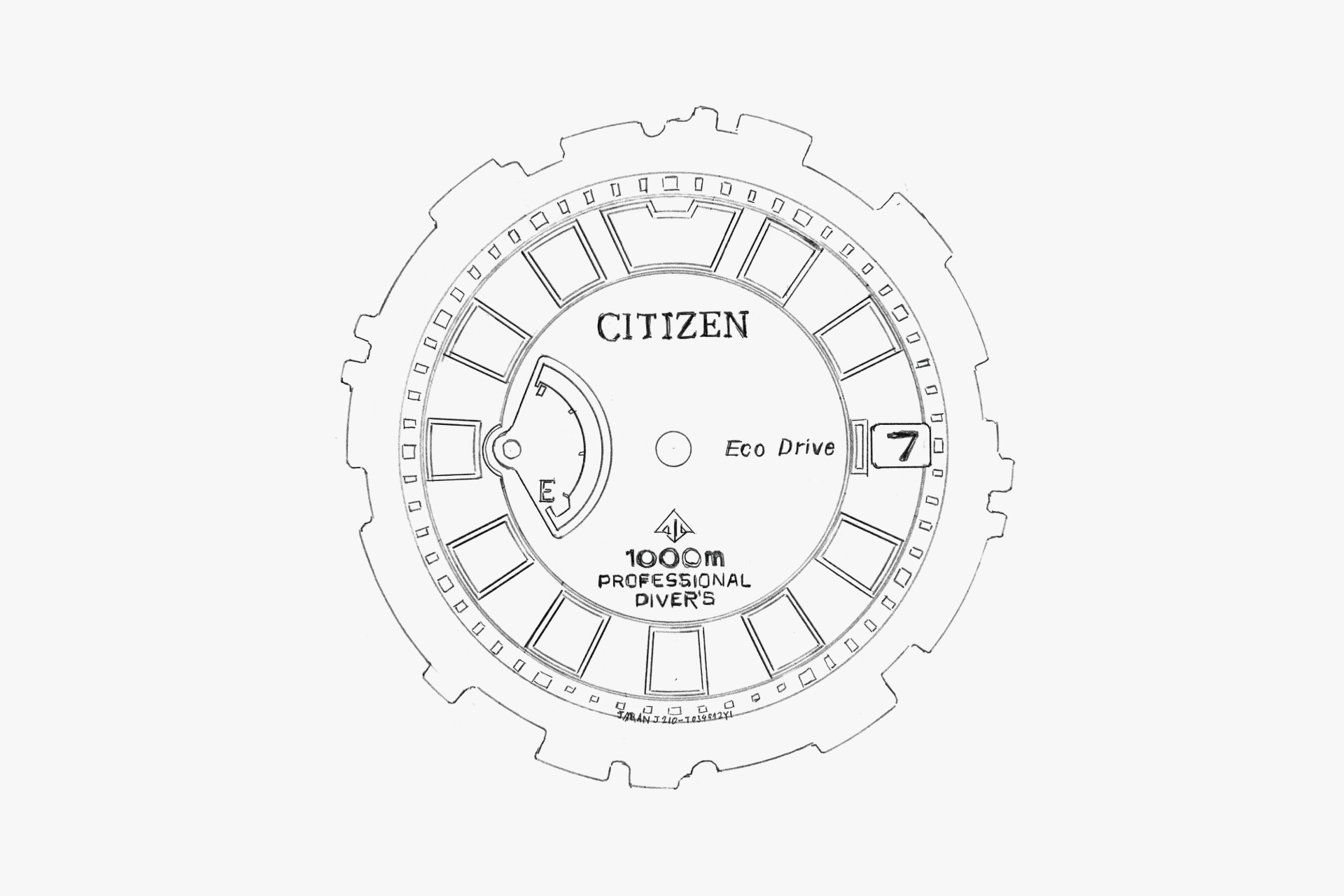

The dial uses molded recesses, protrusions, and patterns to create details that rival those of the case.

Black resin is placed around the mark and polished to be flush with the mark.

Resin is inserted at the base of the crown, and if the crown is not properly screwed into the case, the resin color becomes visible. Like the bezel lock, this specification ensures that the status of life-critical components is always managed.

A hard, voluminous titanium buckle that matches the robust case.

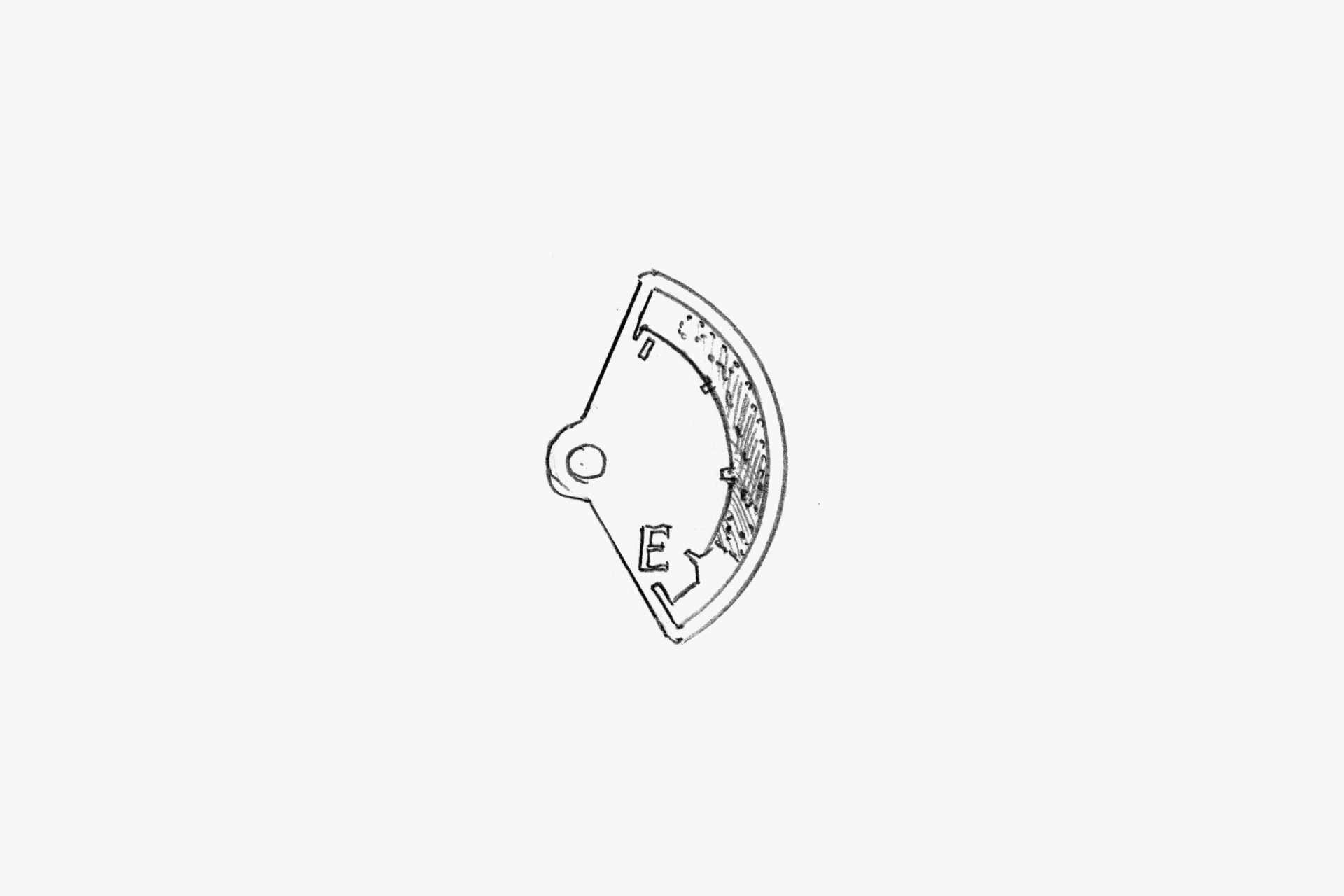

The charge level is indicated by a gradient created with dot printing.

ENGINEER'S EYE

Stop the Invasion

Regarding the external water-resistance structure, we believed it was already established, given our past track record of mass-producing models with water resistance to 1,300 m and 1,000 m. However, after conducting a 15-day pressure-resistance test on this Eco-Drive equipped model, we found that while the hydrostatic pressure test posed no issues, in an ultra-high-pressure environment, helium gas—whose atoms are extremely small—could infiltrate the case interior through minute gaps caused by slight variations in machining and assembly of external components, thereby affecting the movement.

To address this, we measured the internal pressure of the case during the helium pressure-resistance test and set a target to suppress helium ingress to a level that would not affect the movement. We repeatedly refined precision through prototyping and testing by devising the shape of the packing and, for example, using a double configuration of butyl rubber packing with low gas permeability.

It took time, but we completed a watch worthy of the Professional Diver name—one that we can release to the world with confidence.