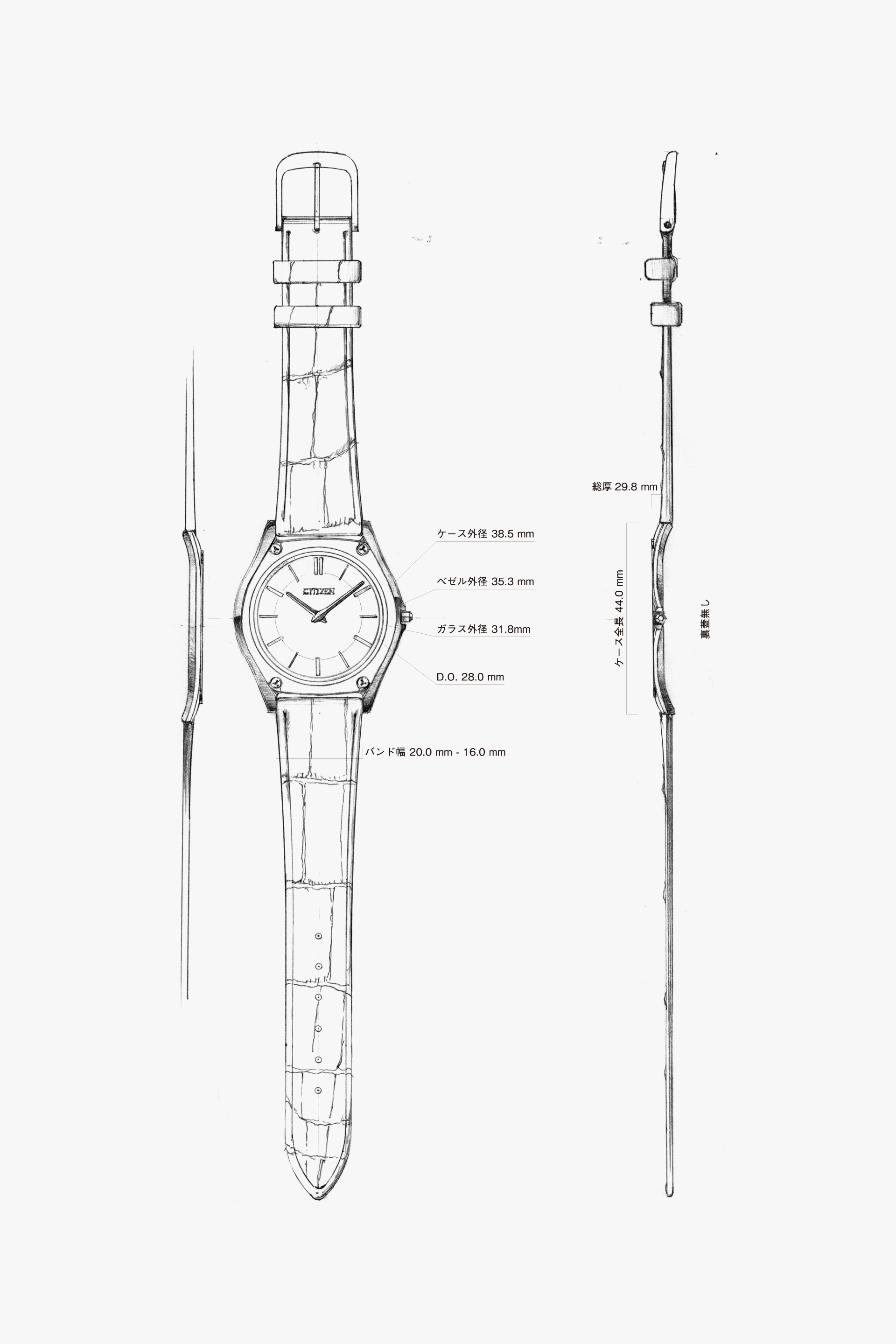

While thinning a watch can have a significant technological impact when it "fulfills its functions," it also imposes design limitations due to the need to "eliminate elements." This model overcomes the strict dimensional constraints of being the thinnest light-powered watch, achieving a form that fully embodies both functionality and decorative appeal.

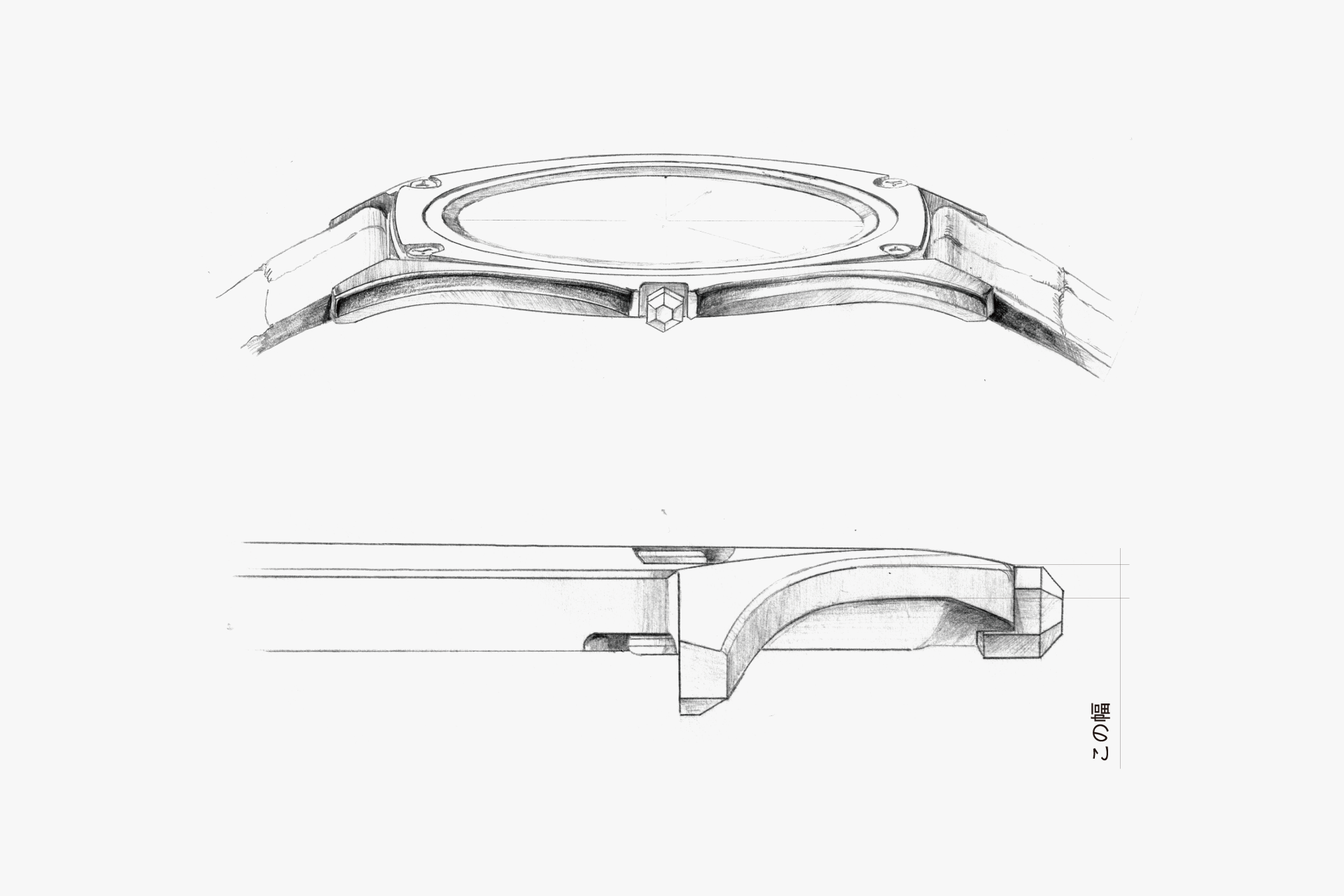

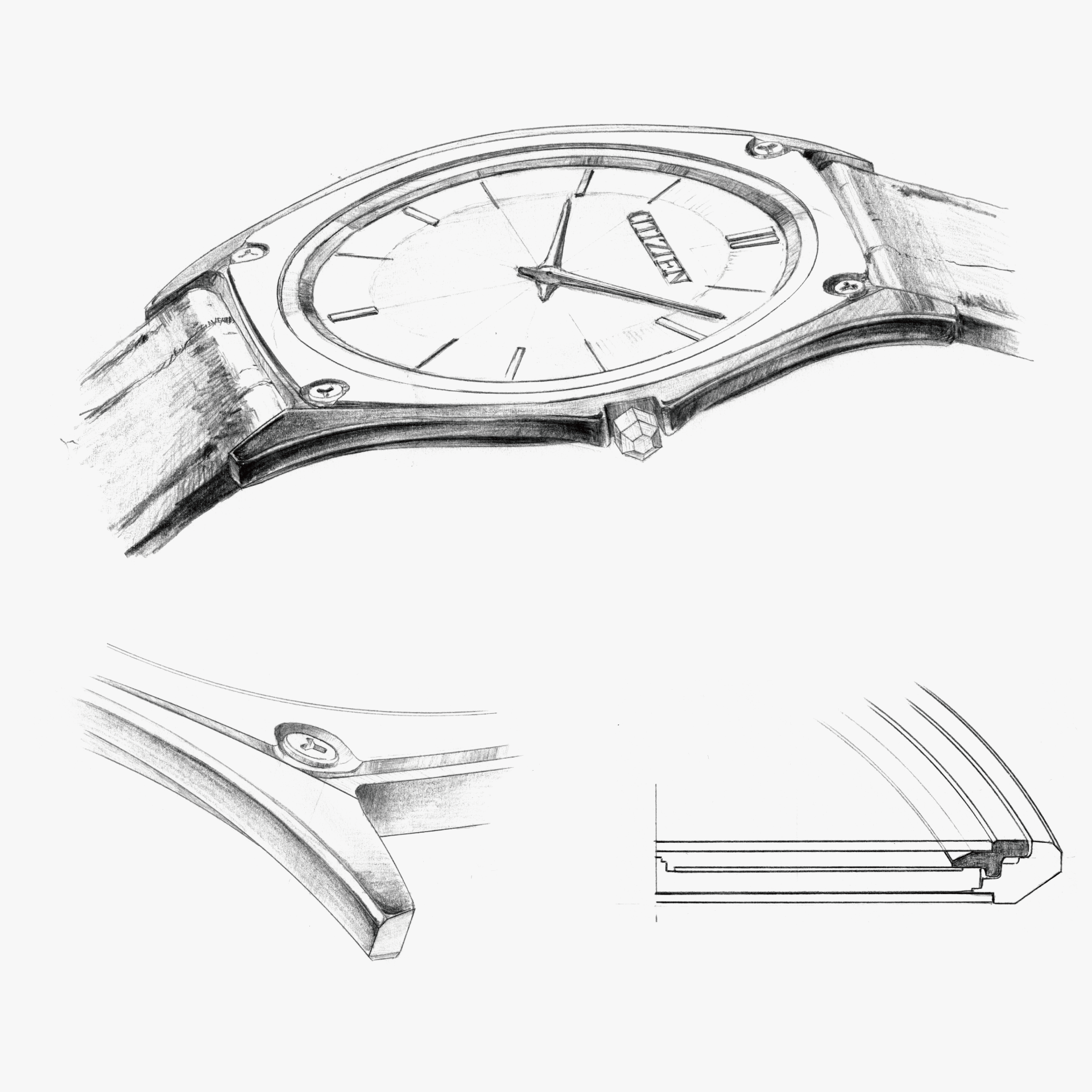

The case uses a composite material called cermet, and both the bezel and case back are sandwiched with binderless cemented carbide, which is hard and highly corrosion-resistant. The joining surfaces of the parts are designed with recesses and protrusions. This structure suppresses the overall thickness while increasing strength, and by adding slopes to the upper and lower side surfaces of the case and the tips of the lugs, it creates a visual effect that makes the watch appear even thinner.

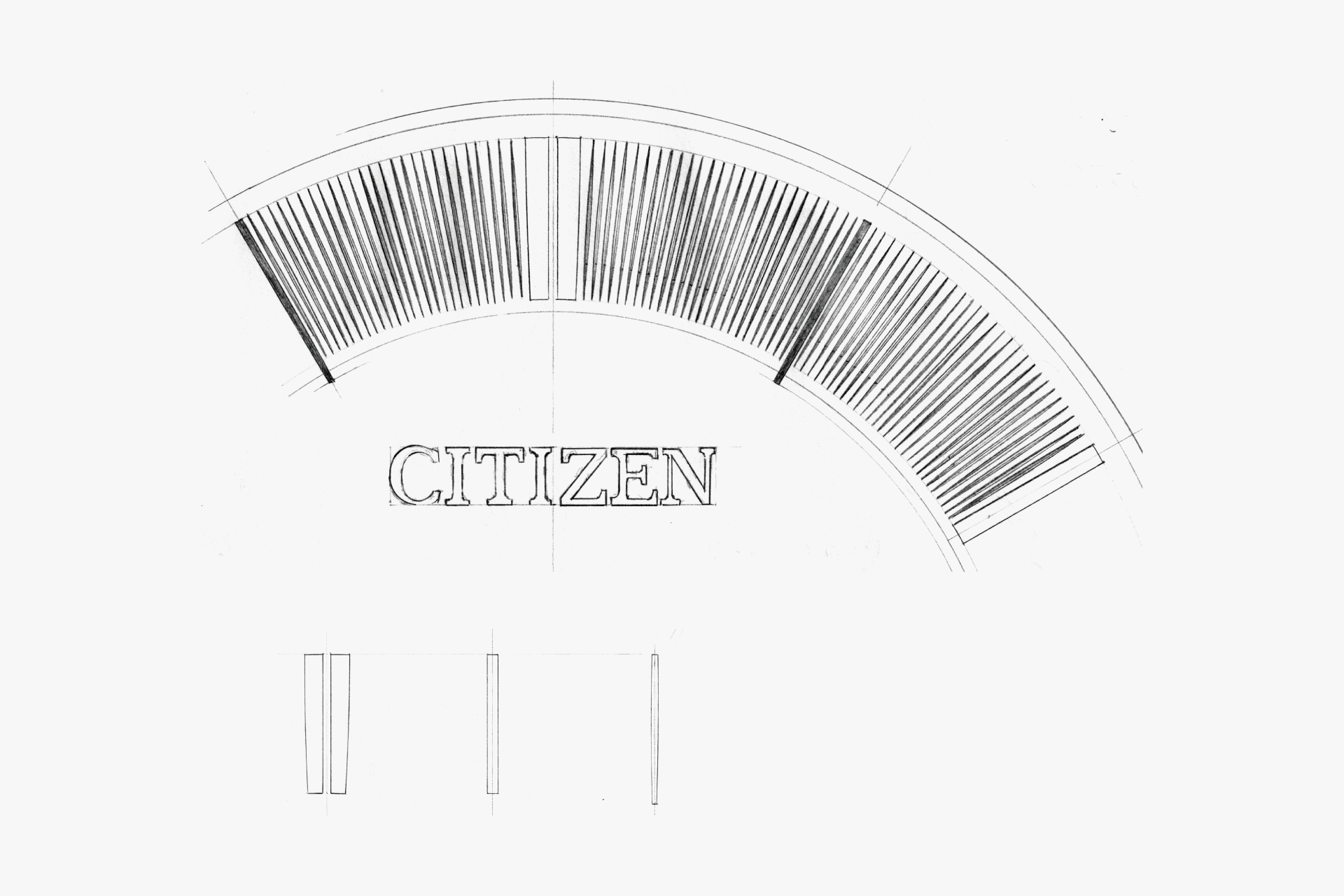

The indexes and radial pattern printing on the dial are thin and long, with the top and bottom of the print tapering, creating an effect that blurs the outline of the outer and inner diameters. This design symbolizes that the watch is powered by "light" and also helps prevent a decrease in light transmittance due to increased printed area.

The hour and minute hands feature both polished and matte finishes, utilizing the blackout effect of the polished surface to make them appear thinner than their actual width, creating a smart look that matches both visibility and the case design.

This is a thin model where you can sense the effort to "captivate" in every detail.

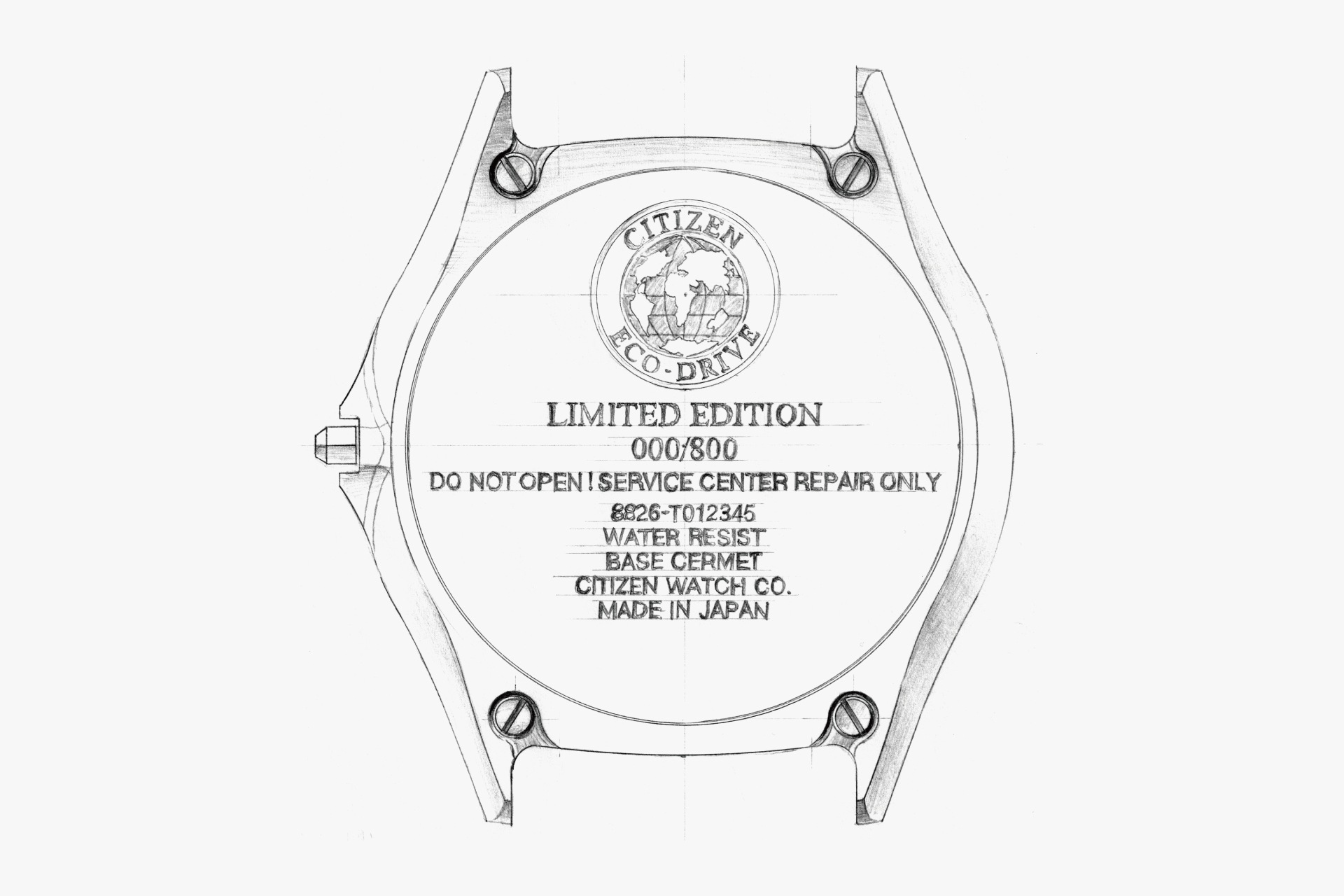

The gold of the case and the silver of the bezel are not plating, but the natural colors of the materials. By using cermet for the case material and binderless cemented carbide for the bezel, the watch achieves a two-piece structure that is both strong and ultra-thin.

The width of the case's side surface is set narrow, incorporating a visual effect that makes the 2.98 mm case thickness appear even thinner.

By expressing the ring-shaped band with radial lines, the edge of the band appears blurred, creating a visual effect as if it is glowing, while also highlighting that it is light-powered.

The center of the hands is finished with both polished and matte surfaces, so the tips of the hands appear sharp from any angle due to the contrast of light.

This model does not have a case back. The case and the round part are separate components made of different materials. By changing the materials, strength is enhanced.

The dividing line between the gold of the case and the silver of the bezel not only meets strength requirements but also features elegant curves, making it hard to believe the design was created under such constraints.

The four screws are set lower than the bezel surface while securing the bezel and case together.

A sense of unity with the wrist when worn. The thin and lightweight appearance is a testament to CITIZEN's craftsmanship, enhancing its presence.

Case cross-section at 9 o'clock: The glass, bezel (black cross-section), and upper surface of the case combine recessed and protruding shapes in the parts to maintain strength while fitting within 2.98 mm.

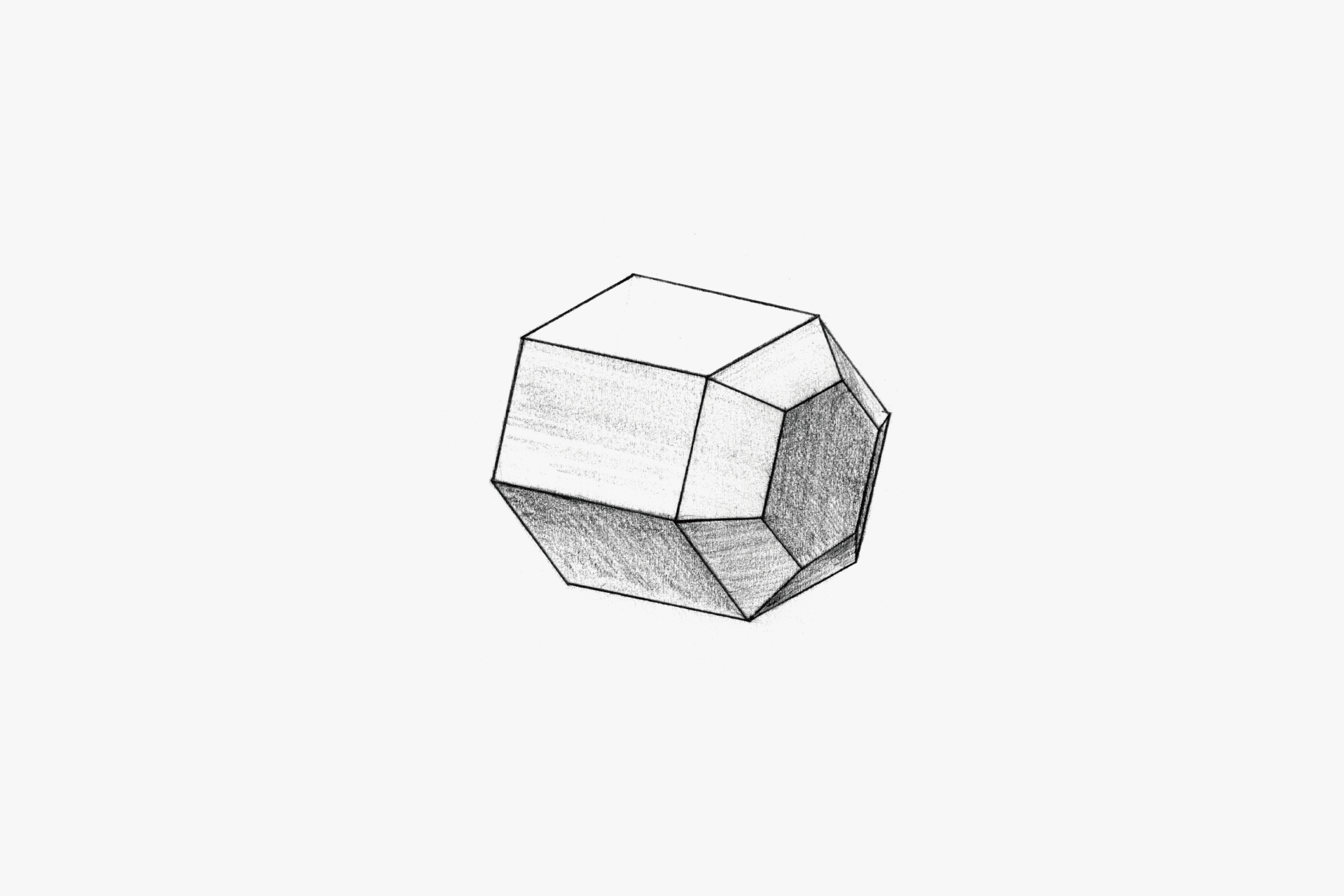

The 2.75 mm crown, designed to match the 2.98 mm case thickness, is hexagonal, increasing the contact area for the fingertips compared to a cylindrical shape, thus improving operability despite its small size.

ENGINEER'S EYE

A Shift in Mindset

On the 40th anniversary of Eco-Drive, in pursuit of the beauty and wearing comfort befitting a watch, we developed an ultra-thin 1.00 mm light-powered movement. To realize a structure in which the parts that drive the watch are concentrated at the center and solar cells surround them, we installed the movement’s base main plate on the case back side—reversed vertically from the usual arrangement.

In addition, for each element, the rotor magnet is directly fixed to a metal gear by laser welding to achieve thinness. A new ultra-thin, high-capacity rechargeable battery was developed. The gears that carry the hour hand and minute hand are controlled with tight tolerances to minimize the hands’ tilt to the utmost. We overcame various development challenges—such as reconciling the motor performance trade-off between lower power consumption and higher torque at a high level by fully leveraging simulations—and created a movement that, despite its ultra-thin profile, secures precision and reliability as a watch.

As a result, most of the more than 80 parts that make up this movement were newly designed as dedicated components.

To achieve a case thickness of 3 mm or less, we newly adopted cermet and binderless cemented carbide for exterior components. We also introduced various new technologies, including reinforced sapphire crystal, an ultra-thin sapphire dial, and bonding techniques for ultra-thin crystals and nameplates.