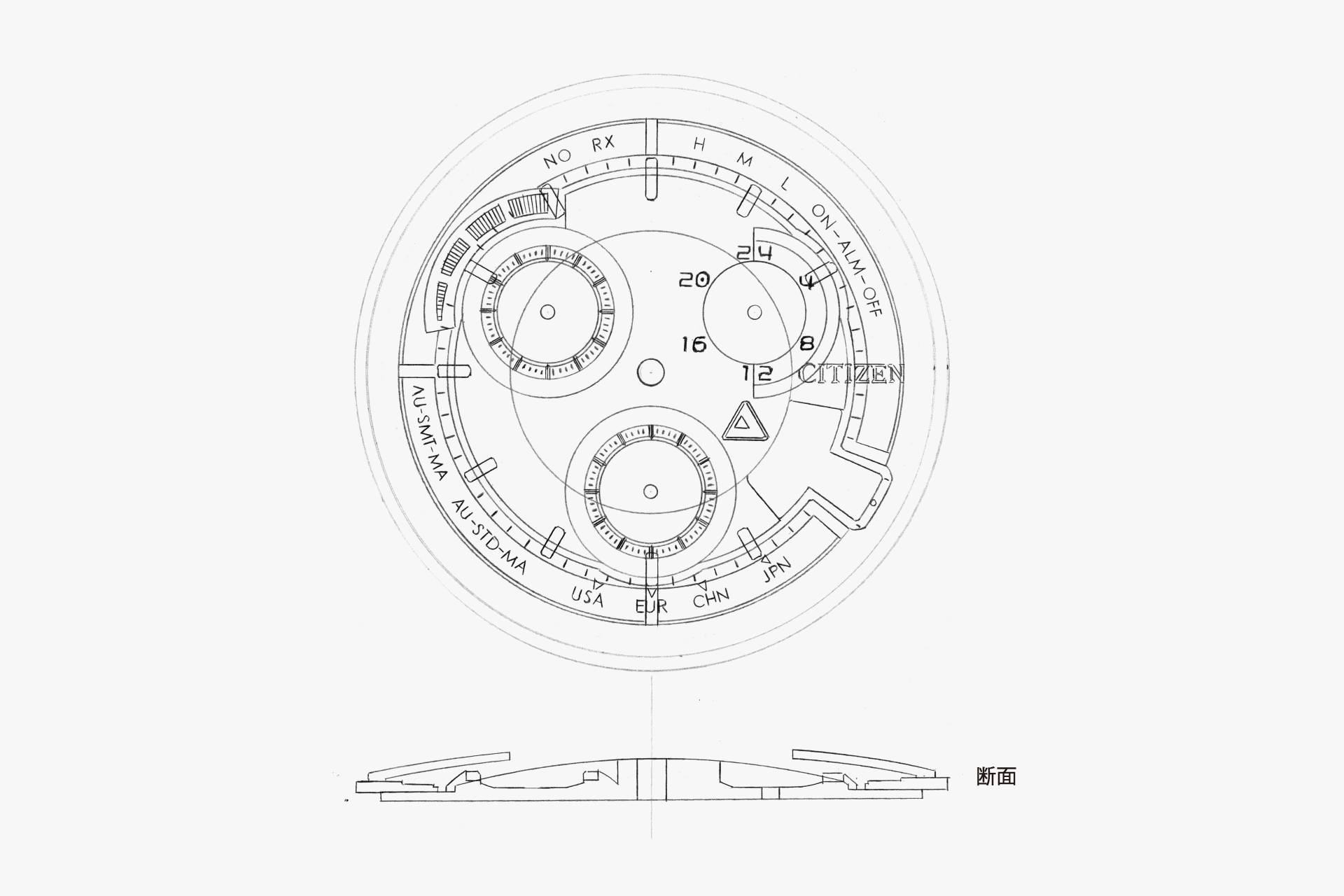

This model takes on the challenge of embodying the theme of "wearing clean energy from light." To express the abstract concept of "cleanliness," elements that would complicate the shape, such as the bezel, have been removed. The surfaces are divided within the same plane, integrating functional components into a unified mass.

Additionally, when using a multifunctional chronograph movement, as many printed indicators on the dial as possible have been eliminated. Instead, the design utilizes the recognition of shapes through reflections from transparent molded parts, and by layering vapor-deposited transparent components, it creates reflected shapes and shadows. Finally, printing is applied to floating parts, making the print appear to drift within a luminous space, thereby expressing the theme of "energy of light."

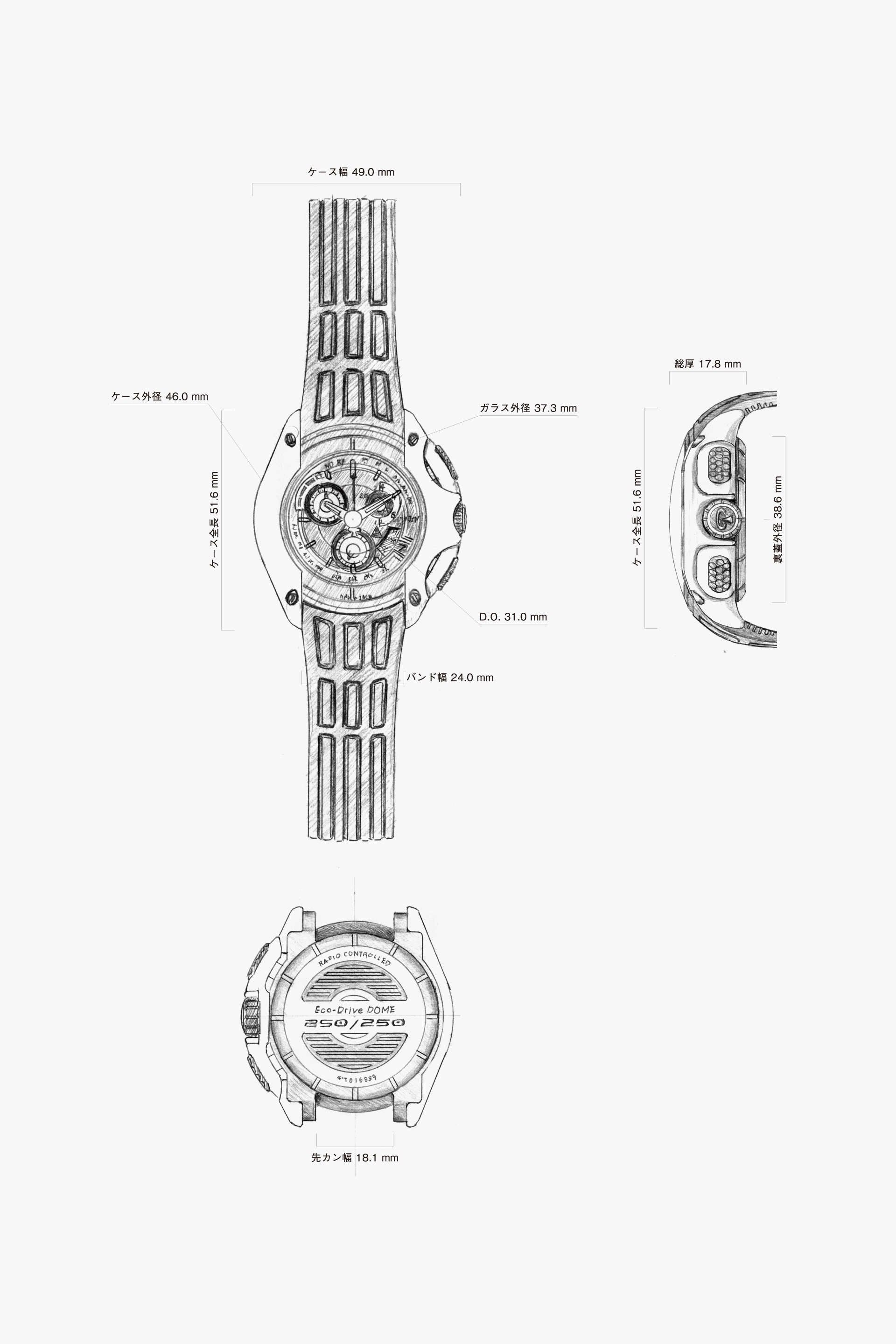

Although the case has a simple design, a three-view drawing reveals that it is composed of many parts, not just what is seen from the front.

Only black and white tones are used, but many parts are incorporated.

The white part of the case is made by applying multiple layers of automotive paint over metal components (titanium). Furthermore, parts that are difficult to stabilize with this paint coating are combined and fixed with screws, requiring considerable effort and time from production to assembly.

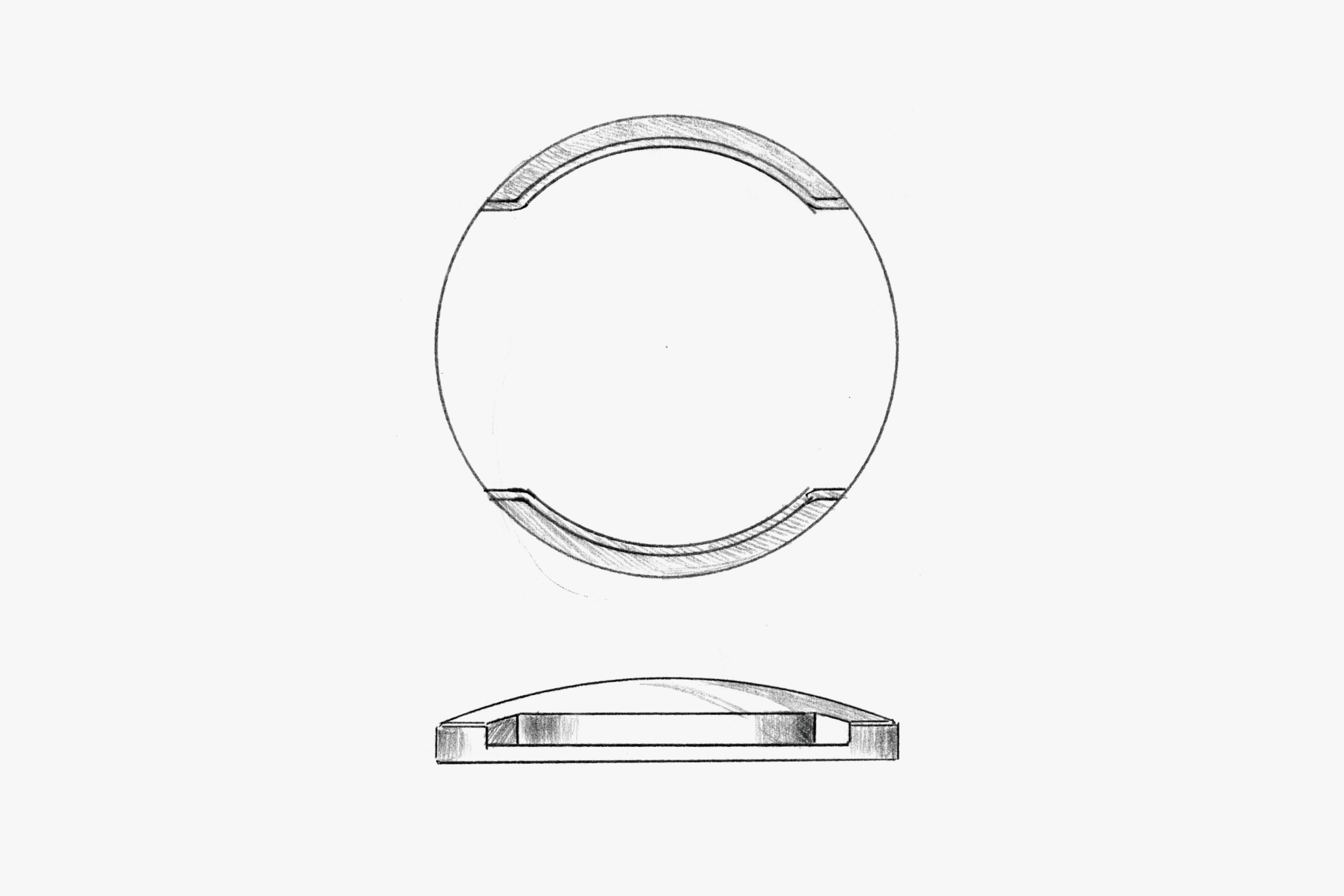

Although the finished watch appears to have an irregularly shaped domed glass fitted to the case, in reality, the outer shape is round. Grooves are cut into the double-domed glass, into which the case is fitted and embedded. This structure enhances the reliability of water resistance.

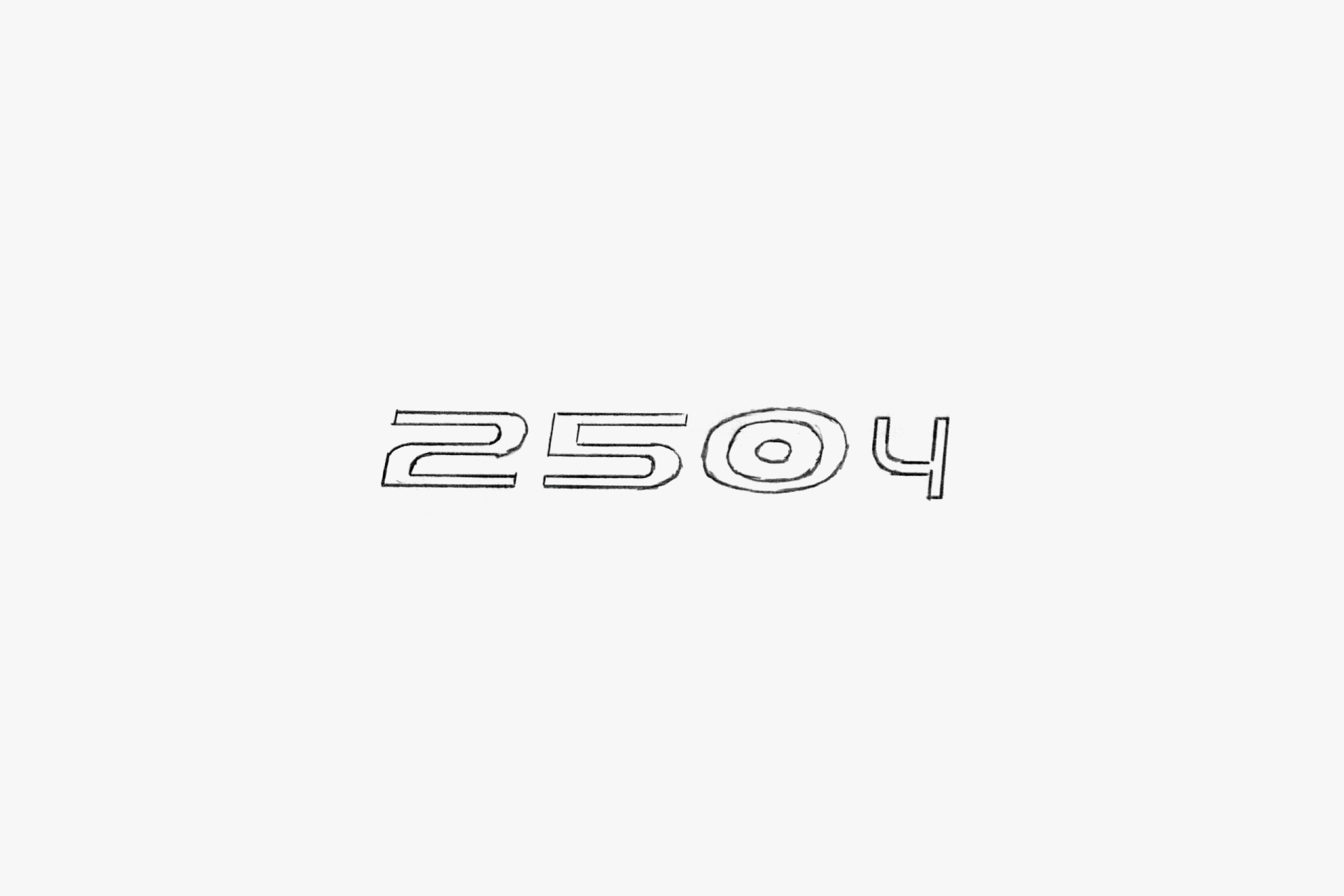

The fonts used for the sub-dials on the dial and the serial number on the case back are chosen to match the futuristic design of the case.

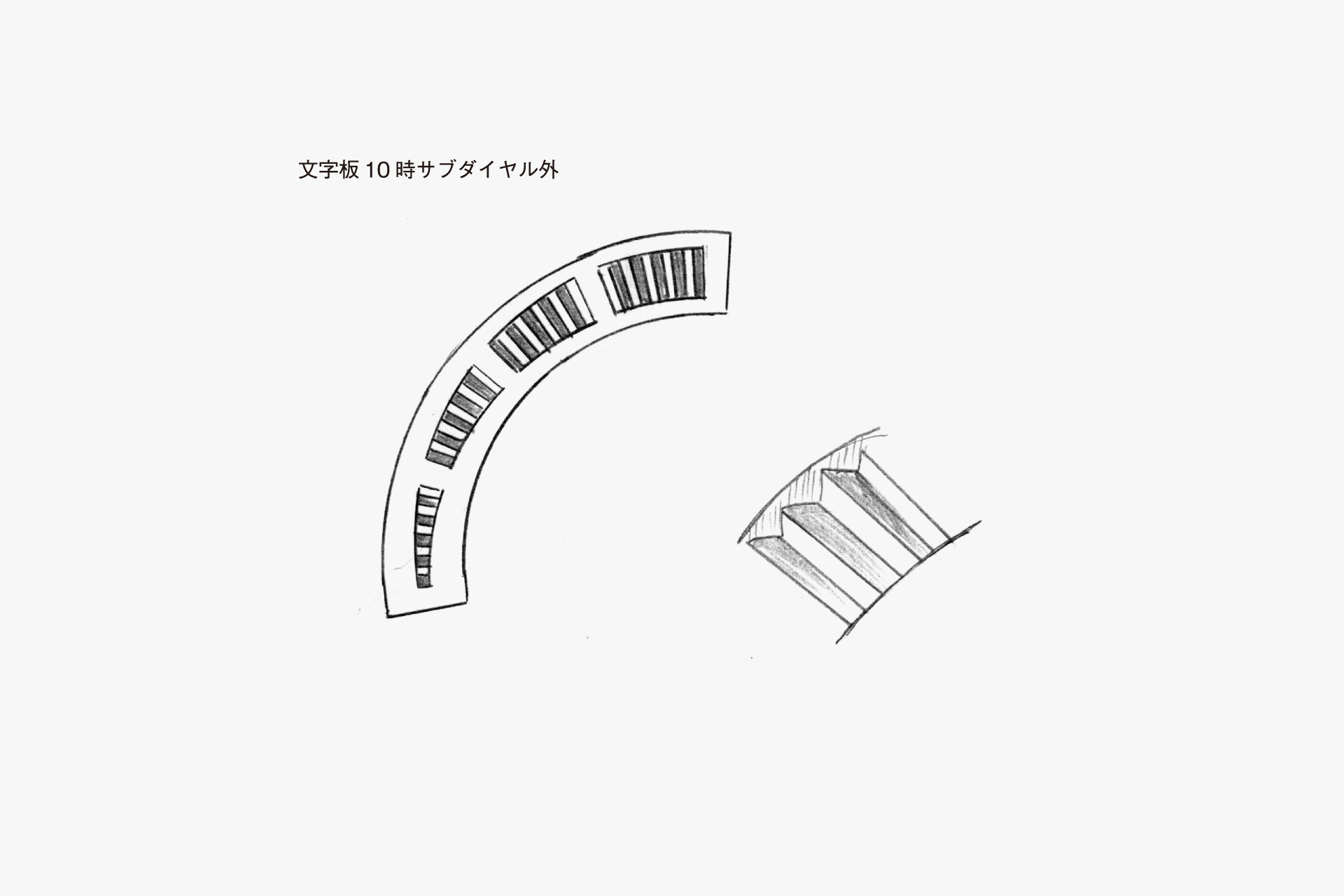

Normally, indicators are shown by printing, but here they are expressed with bellows-shaped molding, allowing them to be read by the reflection of light.

The parts are finely color-separated and intricately shaped with recesses and protrusions, contributing to a sense of luxury.

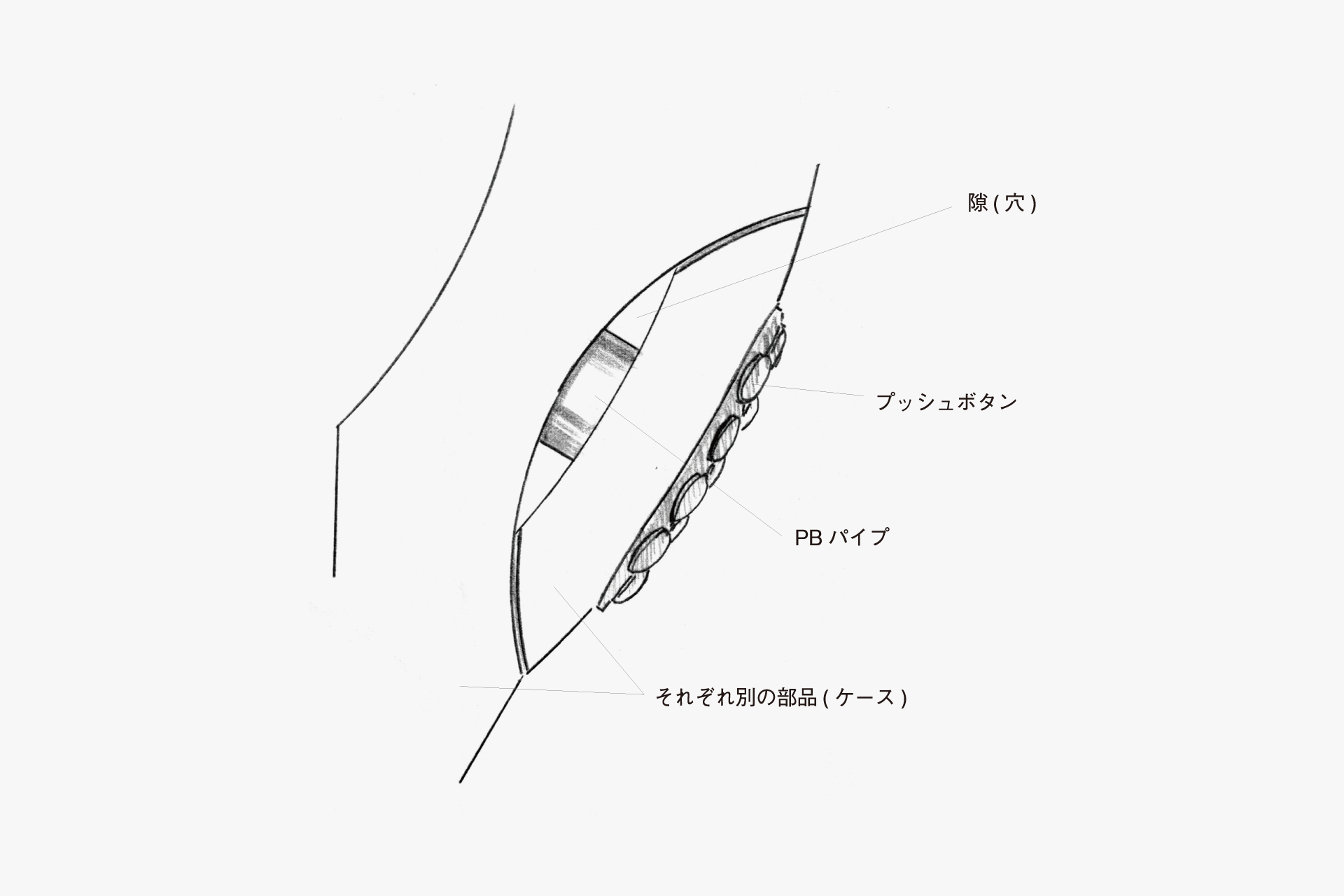

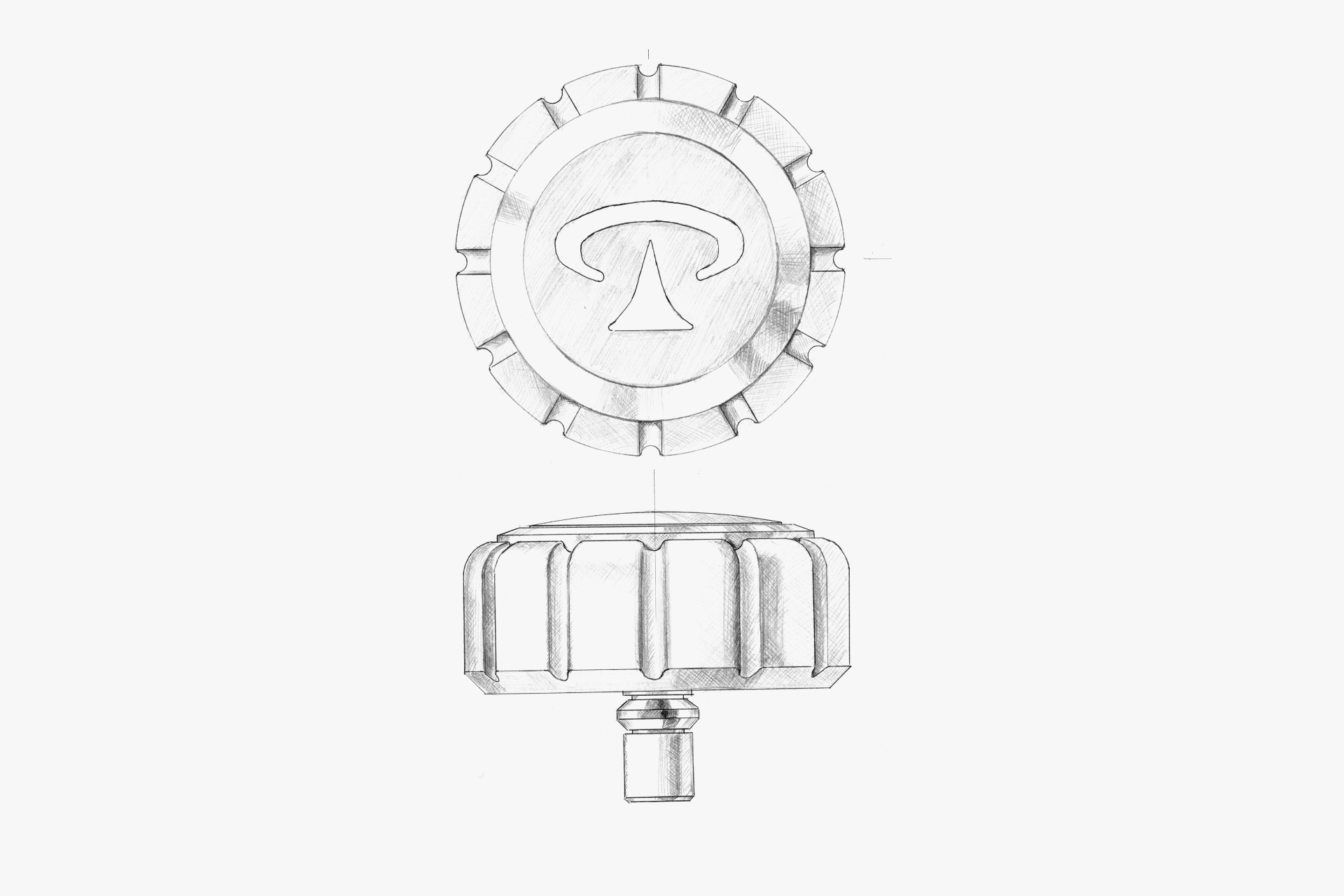

Although small, these parts are composed of multiple components, adding to the sense of luxury.

A shape unique to plastic molded parts.

Multiple highly complex-shaped parts are layered, creating a space filled with transparency and light, where the letters appear to float.

ENGINEER'S EYE

Expression with Light

Developed as the first mass-production model of the “concept model” that CITIZEN has unveiled at Baselworld since 2009 as a vision of the future for its proprietary light-powered Eco-Drive technology. The distinctive white exterior comes from CITIZEN’s original white-pearl painting. Moreover, CITIZEN’s unique know-how in titanium technology is incorporated into the design, achieving both beauty and strength.

The multilayered, laminated structure of the 3D-composed face had long been considered difficult to realize for Eco-Drive due to technical constraints, but CITIZEN achieved it for the first time in this model through its proprietary ultra-precision and microfabrication technologies. This was also the first time that difficult-to-process sapphire glass was realized in a 3D form. The hands were also made three-dimensional by NC machining, and in-house movement manufacturing enabled an overwhelming three-dimensional expression. From the initial idea in 2007, three years of development brought to life a 3D surface technology whose expression changes with light.

As the first mass-produced concept model from CITIZEN, it is one of the timeless works that illuminated the next generation of CITIZEN.